MAXXimum drilling

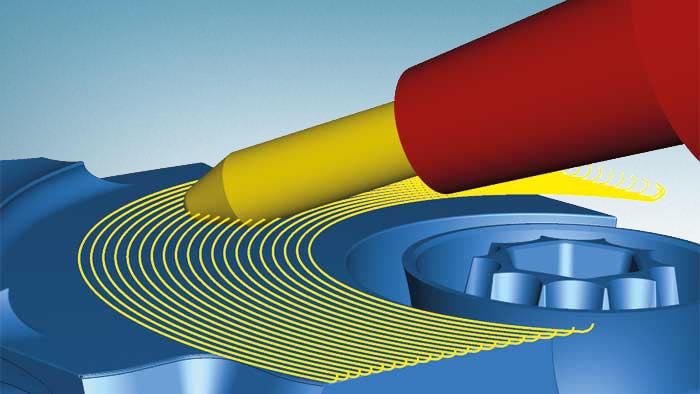

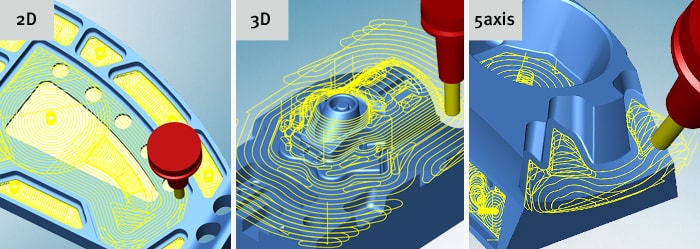

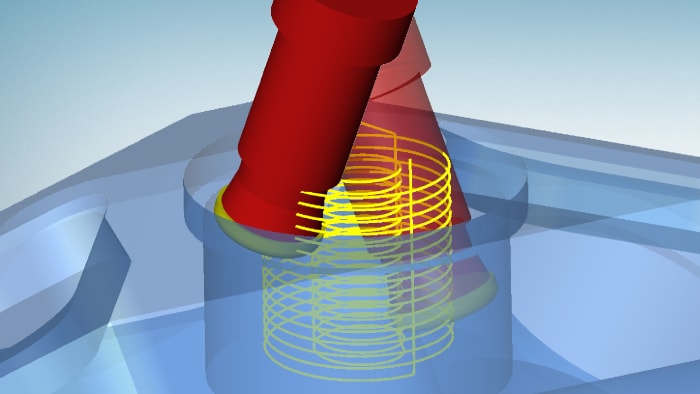

The task: To remove as much material as possible from a circular pocket in an efficient and tool-friendly manner. The solution: 5axis helical drilling.

Simply ingenious

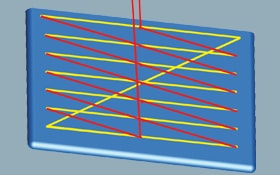

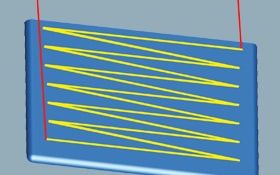

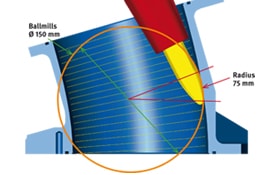

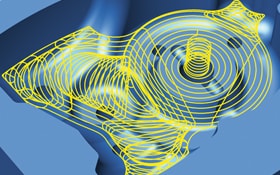

5axis helical drilling involves helical tilt milling. The milling tool is tilted tilted forward in the cutting direction. A second tilt helps to avoid collisions with the hole wall. This strategy is especially suitable for making an opening cut when roughing deep cavities. Material can be removed from circular pockets in a highly efficient and tool-friendly manner. Thanks to this 5axis simultaneous machining strategy, milling tools that are not centre-cutting can also be used. The tool plunges into the material quickly, without the need for any predrilling.

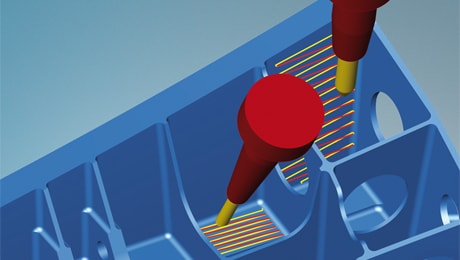

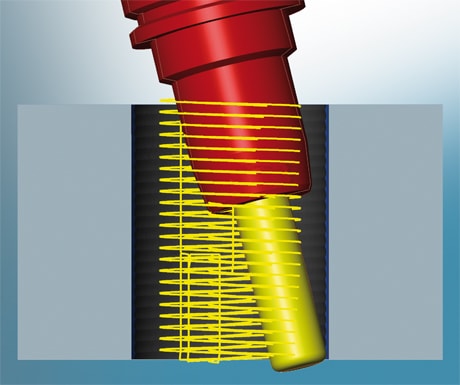

Maximum safety thanks to fully automatic collision avoidance

Maximum safety thanks to fully automatic collision avoidance

Features

- Fast and efficient material removal, especially for tough materials

- Excellent for opening deep cavities using large milling heads

- No predrilling necessary

- Tool-friendly

- Safe removal of chips, even in deep drill holes

- Also suitable for milling tools that are not centre cutting

- Strategy is as easy as programming a drill hole

Details

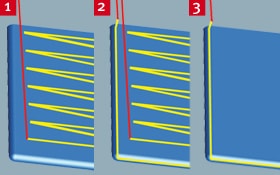

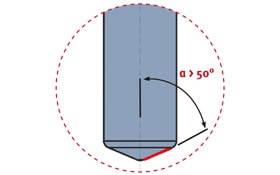

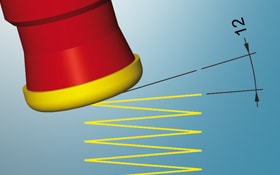

Lead angle

In contrast to conventional 3D machining, a lead angle allows for use of milling tools that are not centre cutting.

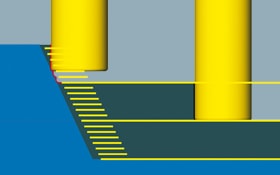

Automatic pitch adjustment

In the event of a collision, this function automatically adjusts the pitch until collision-free machining is ensured.