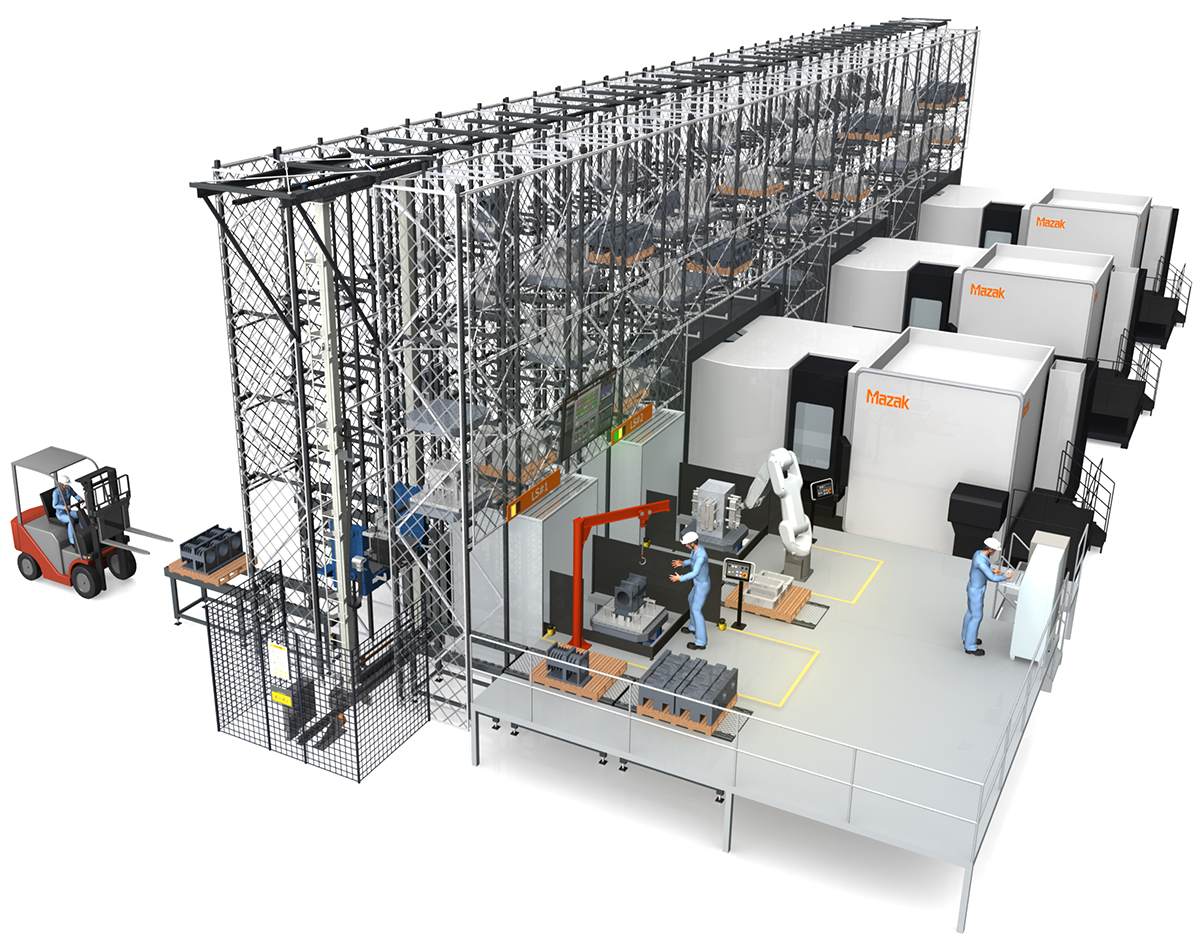

Ease of workpiece transfer and loading/unloading

High speed, high accuracy workpiece transfer and loading/unloading for unmanned operation over extended periods of time. Different specification work loader hands and work conveyors are available for a wide range of Mazak machine tools.

CNC turning centers ・Multi-tasking machines

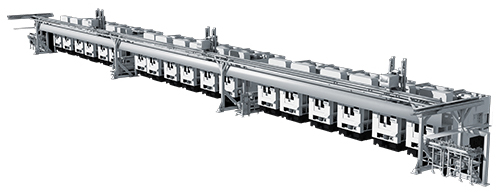

GL series for extended periods of automatic operation

- High speed gantry loader ensures higher productivity

- 2-pallet workpiece conveyor at front and rear allows setup of next job during machining of the current one

- Wide variety of gantry loaders to meet your production requirements

| Applicable machines | Gantry loader |

| CNC turning center MULTIPLEX W series |

GL-100 / GL-150 / GL-200 / GL-300 / GL-400 |

| Multi-tasking machine INTEGREX i series |

GL-50F / GL-75F / GL-100F / GL-150F / GL-200F /GL-300F / GL-400F / GL-500F |

New gantry loader meets a variety of automation requirements

- Flexible installation - conveyor can be located on machine right or left side, measurement equipment can be added and can connect 2 machines

- By adding automatic door and robot I/F, gantry loader can be field installed on QUICK TURNs

- Different specification work loader hands and gantry loaders are available to meet a wide range of production requirements

| Applicable machine | Gantry loader |

| CNC turning centers QUICK TURN series* QT-COMPACT series |

GL-30 / GL-50 / GL-100 / GL-150 / GL-200 / GL-300 |

*Not available for the QUICK TURN 400,450 series

FF Horizontal machining center series

Compact production line with gantry loader

- Designed for large volume production for automotive components

-for the machining of components such as engine blocks and cylinder heads