High productivity and environmental performance

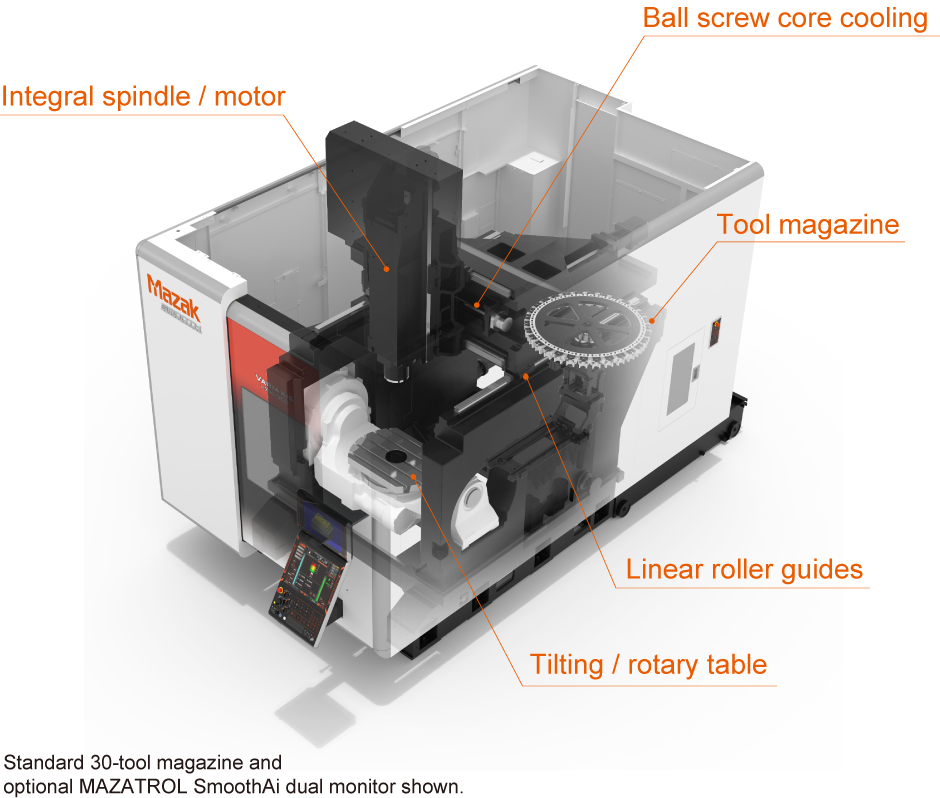

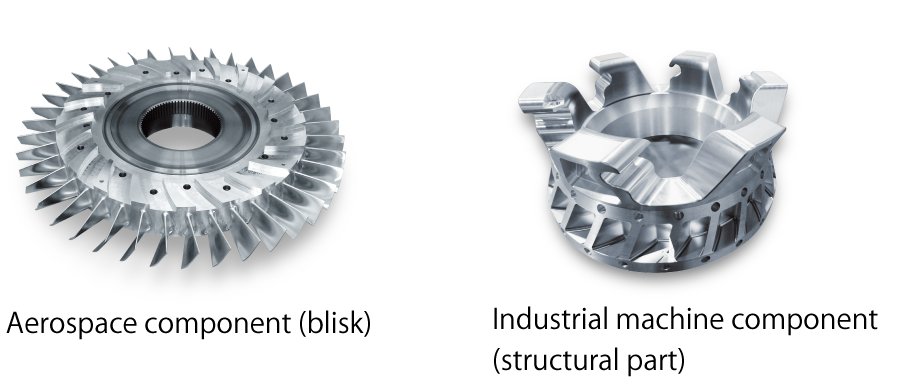

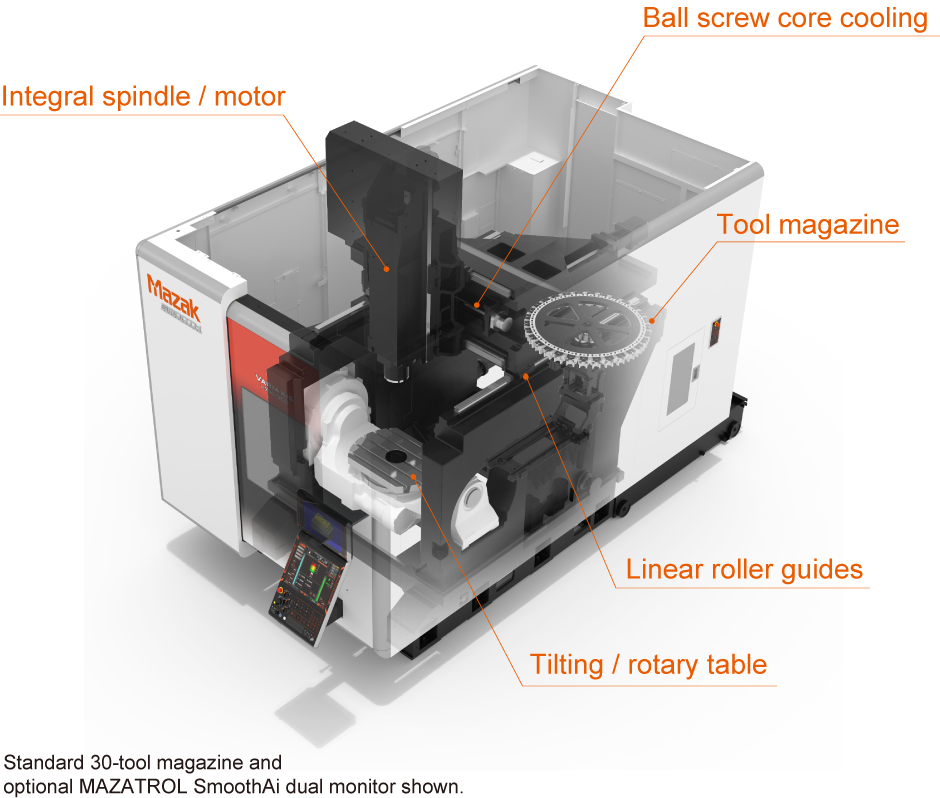

5-axis vertical machining center

- Spindle specifications to meet a wide variety of machining requirements

- High-rigidity full gantry construction ensures stable machining accuracy

- Wide variety of available automation equipments

- Improved environmental performance with energy-saving equipment

Spindle Variation

The highly rigid spindle can perform heavy-duty machining of steel as well as high-speed machining of non-ferrous materials such as aluminum. Highspeed and high-torque options are available.

Standard [ 12000 min-1(rpm) ]

| Output(40% ED) |

22 kW( 30 HP) |

| Max. torque(40% ED) |

71.6 N・m |

| Tool shank |

BT-40 / BBT-40* / HSK-A63* |

*:OPTION

High torque [ 12000 min-1(rpm) ](OPTION)

| Output(40% ED) |

22 kW( 30 HP) |

| Max. torque(40% ED) |

118 N・m |

| Tool shank |

BT-40 / BBT-40 / HSK-A63 |

High torque・high speed [ 15000 min-1(rpm) ](OPTION)

| Output(40% ED) |

46 kW( 62 HP) |

| Max. torque(40% ED) |

200 N・m |

| Tool shank |

BT-40 / BBT-40 / HSK-A63 |

High torque・high speed [ 18000 min-1(rpm) ](OPTION)

| Output(40% ED) |

30 kW( 40 HP) |

| Max. torque(40% ED) |

120 N・m |

| Tool shank |

BT-40 / BBT-40 / HSK-A63 |

High torque・high speed [ 20000 min-1(rpm) ](OPTION)

| Output(40% ED) |

30 kW( 40 HP) |

| Max. torque(40% ED) |

120 N・m |

| Tool shank |

BT-40 / BBT-40 / HSK-A63 |

High torque・high speed [ 20000 min-1(rpm) ](OPTION)

| Output(40% ED) |

42 kW( 56 HP) |

| Max. torque(40% ED) |

161 N・m |

| Tool shank |

BT-40 / BBT-40 / HSK-A63 |

Full gantry construction ensures stable machining accuracy

Minimized vibration during acceleration/deceleration ensures stability for high-accuracy machining.

Automation

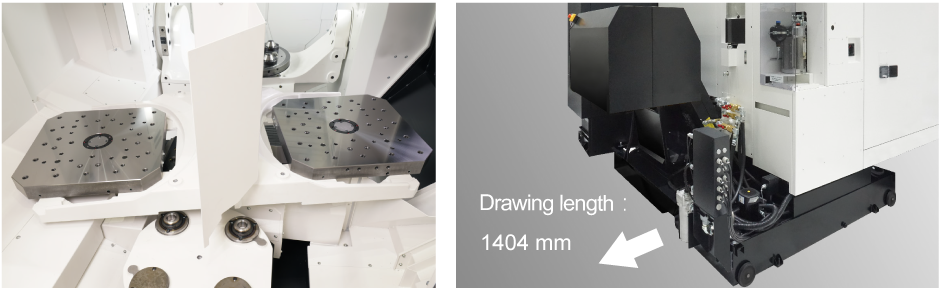

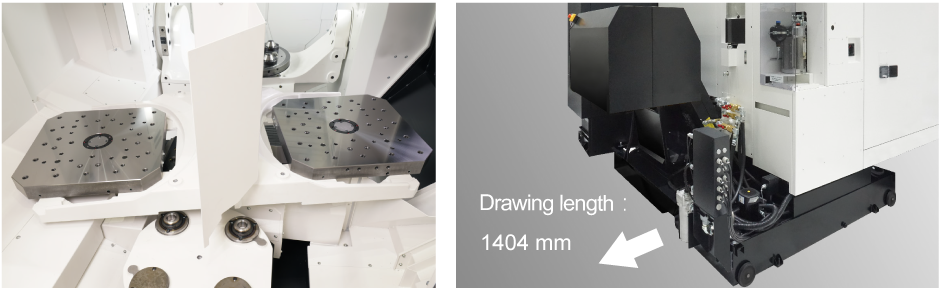

2-pallet changer (OPTION)

For higher productivity, set up the next workpiece during machining of the current workpiece. The 2-pallet changer offers a compact design and is suitable for mass production. Reduced length to pull out the rear conveyor saves space in the maintenance area.

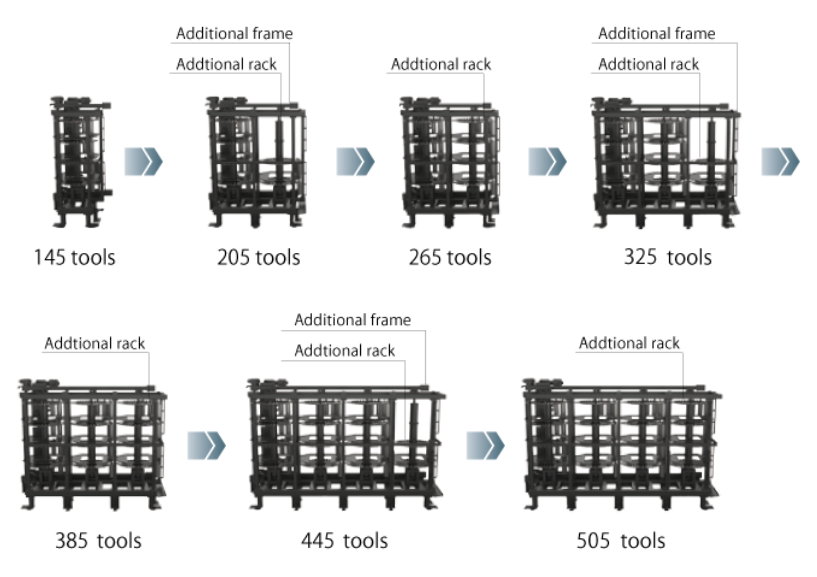

MPP (MULTI PALLET POOL)(OPTION)

The MPP (MULTI PALLET POOL) is a system to meet the increasing worldwide demand for automation. It is designed to provide high productivity in the production of a wide variety of parts in small size lots.

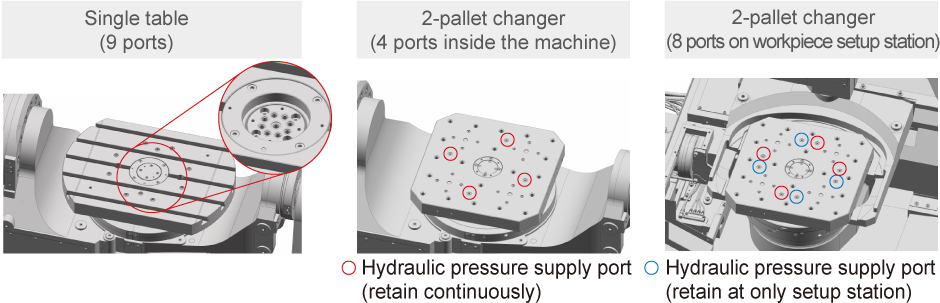

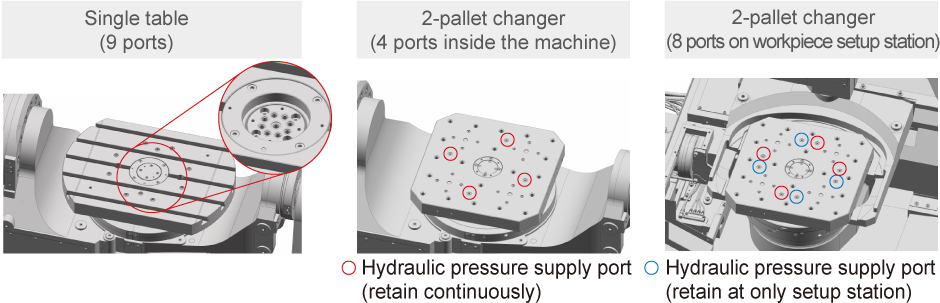

Preparation for hydraulic fixtures(OPTION)

Continuous power is supplied through the pallet for hydraulic fixtures. Pneumatic fixtures also are available.

Maximum number of ports:

・ 9 (single table)

・ 4 ports inside the machine (2-pallet changer)

・ 8 ports on workpiece setup station (2-pallet changer)

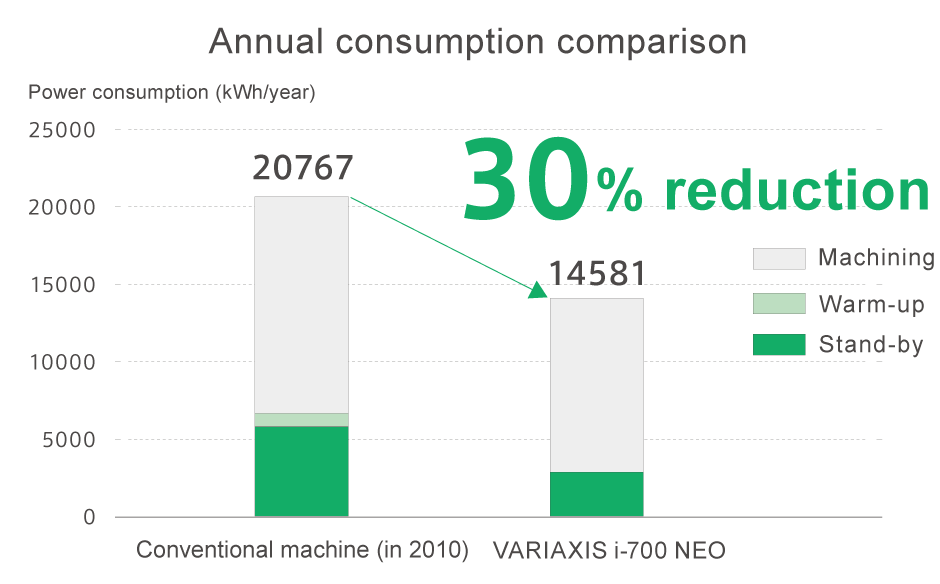

Environmentally Friendly

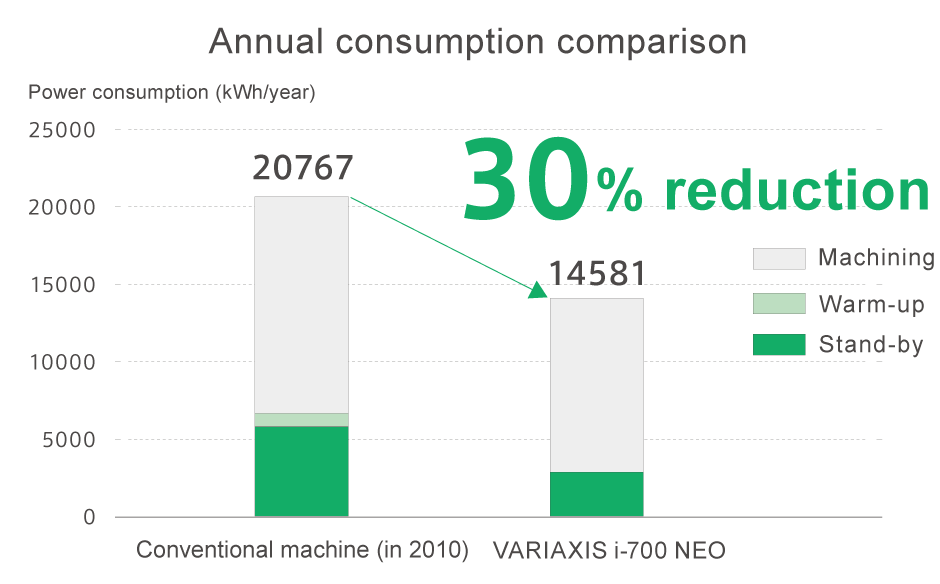

Energy-saving equipment reduces power consumption

◎Hydraulic unit utilizing accumulator

◎Inverter type chiller unit

◎Reduced warm-up time by stable machining accuracy

【Measurement condition of energy consumption】

Operation rate:Machining 75% Stand-by 5% Power-OFF 20%

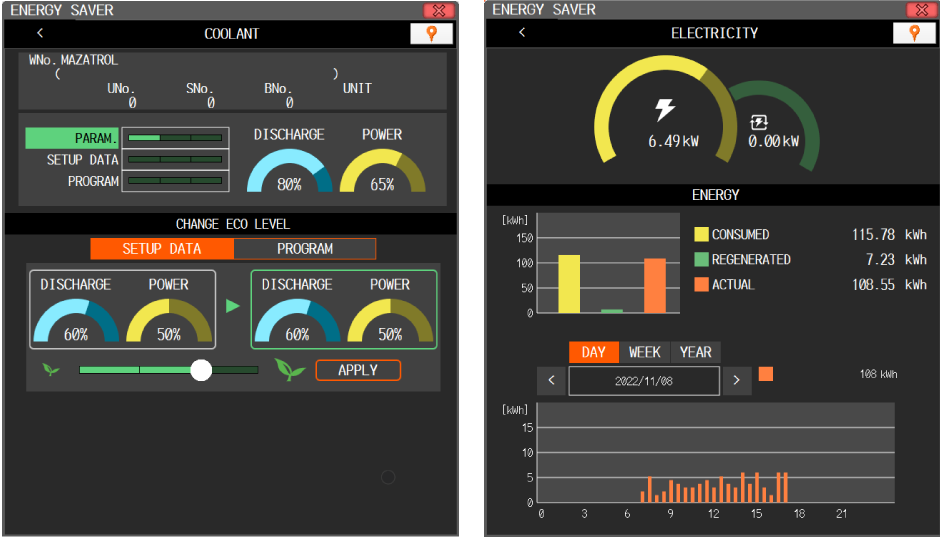

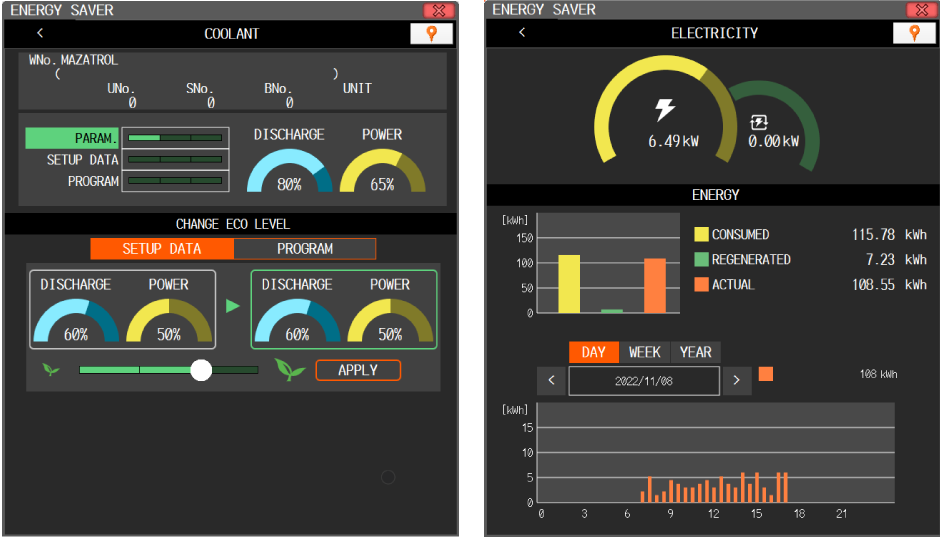

Energy saver

Energy consumption and the regenerative power produced through the energy saving equipment can be viewed visually on the CNC system - control/management of coolant and other equipment.

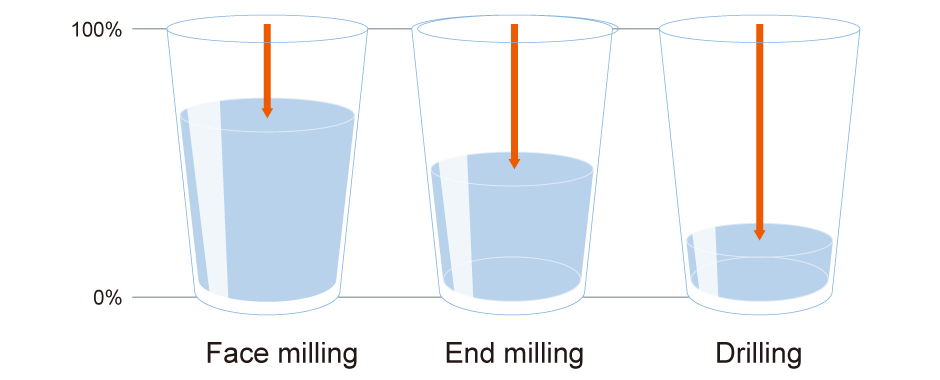

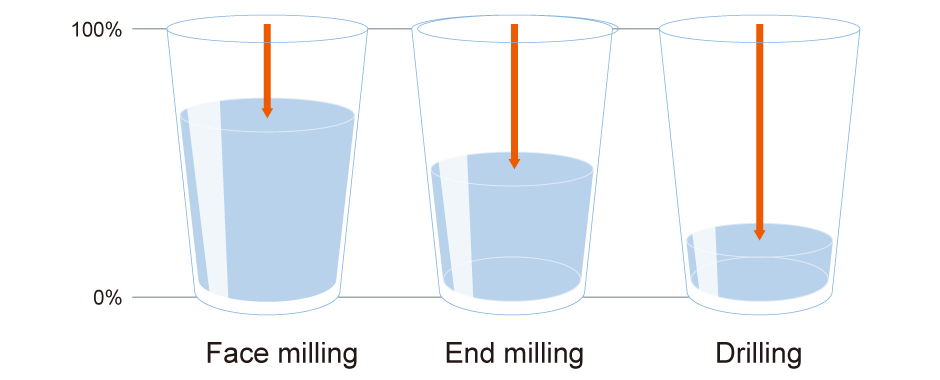

Smooth coolant system(OPTION)

Optimal control of coolant discharge amount

Energy saver automatically determines the optimal coolant discharge for energy-saving machining.

◎The cutting volume is calculated by simulation

◎The optimal discharge amount is automatically determined

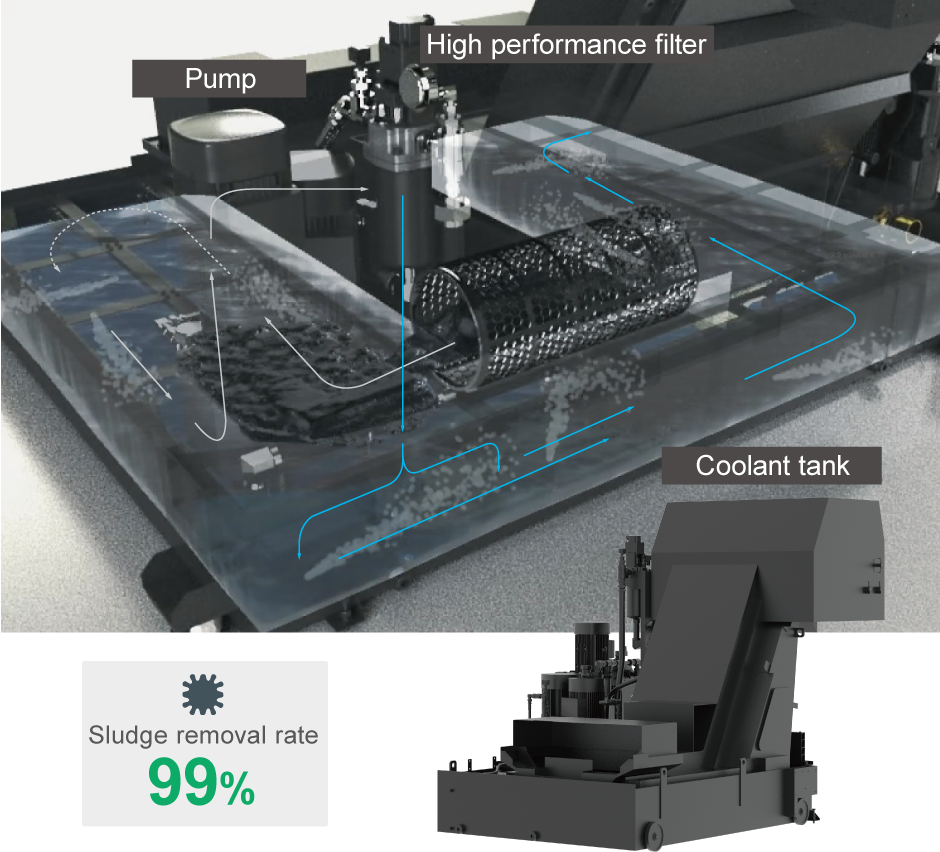

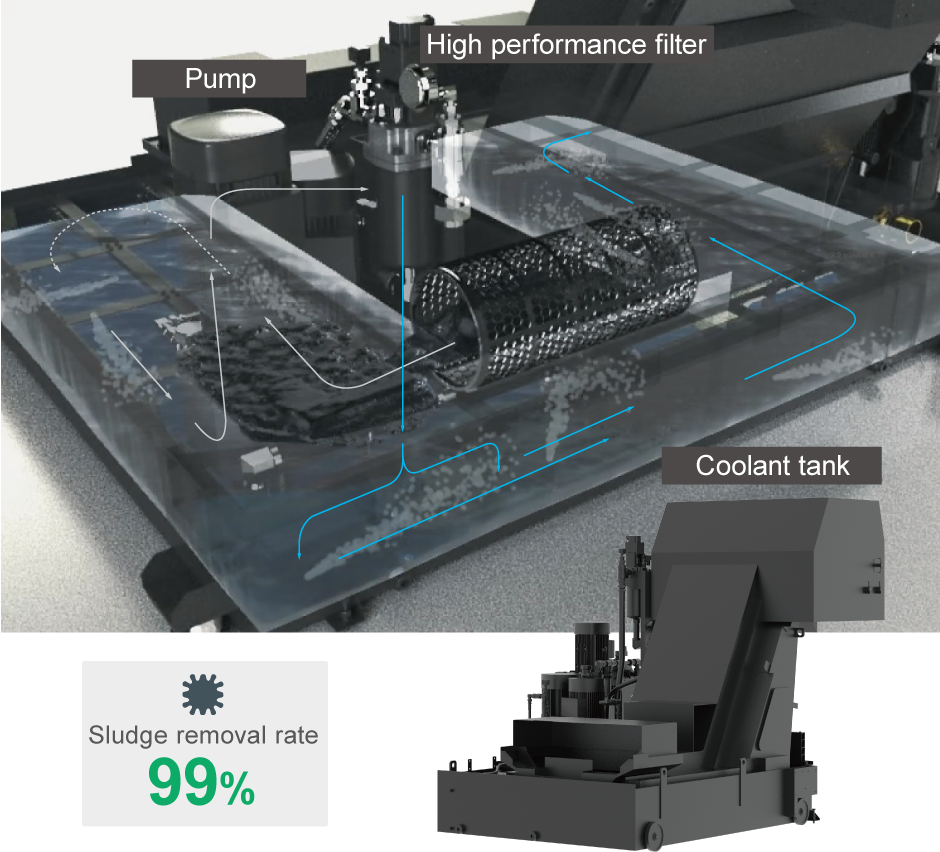

Energy-saving coolant system with sludge removal performance

◎No need to frequently clean the tank

◎High performance filter removes 99% of sludge

◎Reduced running cost / environmental impact

Next generation MAZATROL Smooth CNC system

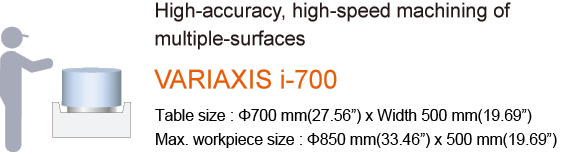

Machine Specifications

| Mazak Variaxis i-700 NEO |

Values |

| Spindle |

Spindle Taper |

BT40 |

| Maximum Speed |

12000 rpm |

| Magazine |

Number of Tools |

30 |

| Rotary Axes |

Table Tilt (A axis) |

150 degrees |

| Table Indexing (C axis) |

360.0000 degrees |

| Feed Axes |

Travel (X Axis) |

630 mm / 24.80 in |

| Travel (Y Axis) |

1100 mm / 43.31 in |

| Travel (Z Axis) |

600 mm / 23.62 in |