Losma Spring coolant filter, neat oils filtration, emulsion filtration, industrial coolant filtration, machine tool coolant filtration.

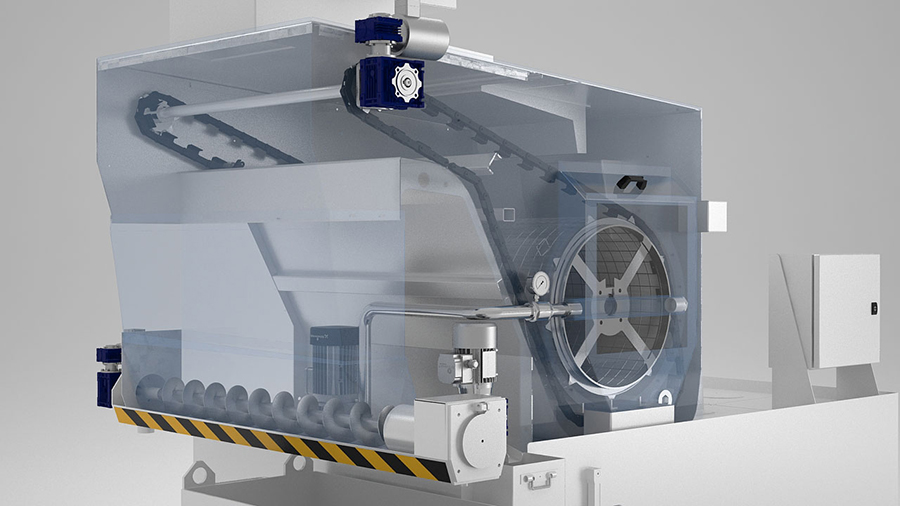

Losma Spring is a self-cleaning drum filtration system, with permanent metallic net, suitable for removal of magnetic or non-magnetic particles from neat oil or emulsion.

- Restorable Stainless steel metallic net

- Dredge system for mud discharge

- Completely customizable

- Autocleaning System.

Unit tested

Losma guarantees that every single unit is individually tested through strict control procedures. Each unit is issued a test certificate for quality and function.

Eco-friendly

Losma Spring system uses metallic filter net which is cleaned thanks to a self-cleaning system.

Reducing costs

Losma Spring system does not use consumable material, reducing costs for maintenance and industrial waste disposal.

Technical information

Losma Spring is available in 9 sizes with flowrates ranging from 25 to 1000 l/min of neat oil and from 50 to 2000 l/min of emulsion. The drum’s filtration efficiency can be customized according to customer requirements.

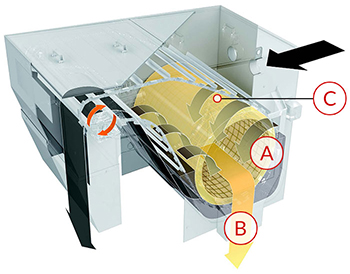

Operation

- The metallic filter net covering the drum is clean (A). the dirty coolant passes through it depositing the pollutant particles and goes through the discharge opening (B). from here the clean coolant falls into the collection tank positioned below, from where pumps will transfer it back to the machine tool. During this phase the drum does not rotate and the dredging system is stationary. The polluting particles deposited on the filter net forms the actual filtering layer which can also reach a thickness of 10-15 mm.

- As the filter net gradually gets dirty, the liquid level increases. The dirty coolant continues to deposit pollutant particles onto the drum surface, while the drum and dredging system (C) are still. The filtration level improves due to the thickness of the mud deposited on the filter net.

- Coolant cannot pass though the filter net any longer – filter net clogging cycle is complete this phase is when the best filtration level is reached. The longer the filter operates under these conditions the better the average filtration will be. When the coolant reaches the maximum internal level allowed, a self-cleaning cycle is started automatically. At the end of this phase the coolant level descends and the filtration cycle begins again.

Optional

1. DMD

Pre-filtration system with rotating magnetic discs for the separation of magnetic polluting particles from coolant.

2. Magnetic dredging bed

To facilitate ferromagnetic elimination.

3. Skim

Superficial oil skimmer, it allows to lengthen coolant quality and eliminate odors generated by anaerobic bacteria.

4. Collecting tank

For clean liquid to be sent back to machine tool.

5. Mud Compactor

Used to reduce the volume of mud intended for disposal and for reducing the liquid contained therein. The obtainable compacting level can change on the basis of mud, liquid used and many other factors such as cycle timing. The reduction in volume and of humidity is obtained through pressing with static load. The volume efficiency reduction is from 40% to 20% and for liquid residual from 30% to 10%.

6. Transfer tank

To collect dirty liquid for feeding the filter.

7. Electrical panel

For powering the system, control and command all signals.

8. Pumps

For pressure from 0,1 to 100 bar for returning clean liquid.