Ever since the creation of the first all-metal lathe in 1751, manufacturers have depended on highly flexible and precise “mother machines,” the metal cutting equipment used to produce all other factory equipment. More than 200 years later, Mazak contributed to this effort with its Slant Turn 40 ATC Mill Center, which gave manufacturers the ability to mill and turn on a single machine platform. Today, Mazak offers a comprehensive range of solutions – the Five Levels of Multi-Tasking – designed to ensure that each manufacturer has an option that suits their unique needs.

But how much Multi-Tasking does a manufacturer need? What level is right for your part-processing requirements? Machine models like the Mazak Quick Turn series span multiple levels of Multi-Tasking to address this issue. As a result, while a manufacturer that simply needs highly productive turning can use the base Mazak Quick Turn model, additional “M” (milling), “S” (second spindle) and “Y” (Y axis) packages may be added to reach as high as the second level of Multi-Tasking.

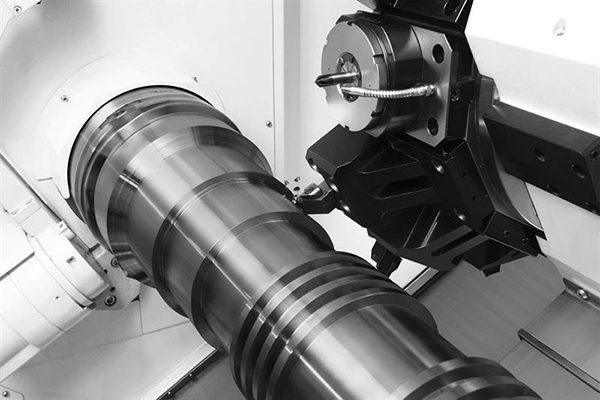

For Level 1, Mazak Quick Turn series machines with the “M” package feature a rotary milling spindle. With a single turning spindle with programmable tailstock and a drum-style rotary-tool turret, machine shops are able to perform many more operations in a single setup, including turning, milling with C axis, drilling and tapping operations. As the remaining levels of Multi-Tasking depend on the presence of this turret, all machines other than the base Mazak Quick Turn models include this “M” package.

At Level 2, the “Y” package introduces Y-axis functionality to the Mazak Quick Turn’s drum turret. Not only does this increase the range of possible part geometries, but it adds off-centerline machining capabilities to the mix – a feature further improved by the special high-gain servo-control turret/feed-axis motion equipped on Mazak Quick Turn MY and MSY models, which allows for rigid and precise positioning along with smooth and quick axis acceleration/deceleration. And for the complete Level 2 experience and to enable true single-setup, Done-in-One machining manufacturers use the “S” package, which adds a second turning spindle to the machine to automatically pass parts from one spindle to the other to work on both sides of a part. For both the main and second spindles, Mazak provides a rotary C axis with 360,000-degree positioning or full C-axis contouring capabilities.

With the complete MSY package, manufacturers have the ability to realize many of the benefits of Multi-Tasking, but further levels are available for those who need even more advanced functions. Level 3 introduces the manufacturing capabilities necessary for 4-axis simultaneous machining and 5-axis tool tip positioning, while Level 4 offers full, simultaneous 5-axis machining. And for the utmost in part-processing flexibility, manufacturers can opt for a HYBRID Multi-Tasking machine, which brings operations like hobbing, power skiving and grinding.

As manufacturers of all sizes and in every industry increasingly move away from high-volume production to high-mix/low-volume manufacturing strategies, it has become more important than ever to emphasize Multi-Tasking. Single-setup machining saves time, reduces risk and improves part quality – and as more processes get introduced, Multi-Tasking will get pushed to even higher levels.

Click here to take a look at the Mazak Quick Turn series.