One of Australia’s true world-class manufacturers, Lovitt Technologies Australia continues to invest in manufacturing capacity and capability.

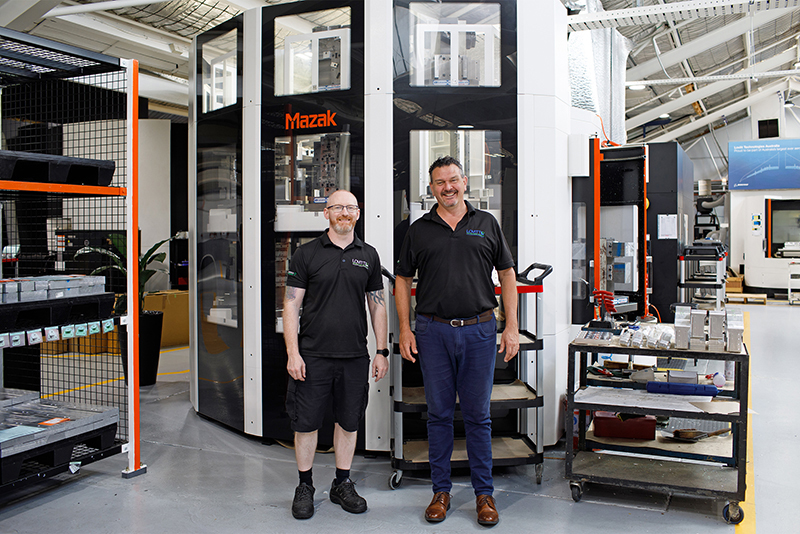

↑ Lovitt’s Manufacturing Director Bruce Ramsay (left) with Team Leader Luke Meggs, showing off the company’s new Mazak Vortex e-1600V/10.

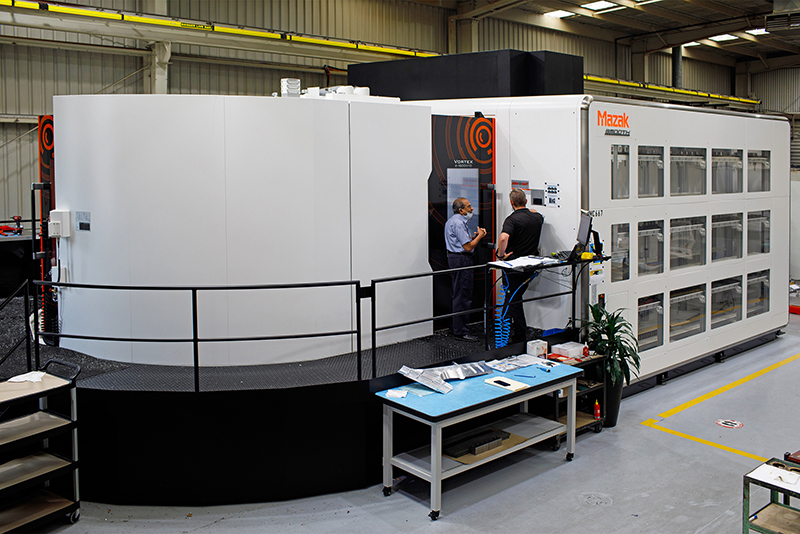

↓ The Mazak Vortex e-1600V/10 with two pallet changer and 162 tool magazine.

Lovitt Technologies Australia is a leading manufacturer of complex, precision engineered, structural components and assemblies for commercial, business and military aerospace platforms. Central to the company’s current and future success is the selection and use of best in class CNC machining equipment.

Flying in the face of the impact of the pandemic on Australian business and the economy, the company made two very significant investments during 2020 and 2021: a Mazak Vortex e-1600V/10 five-axis machining centre, and a Mazak Variaxis i-700 five-axis machining centre equipped with a Mazak Multi Pallet Pool (MPP) – all supplied by John Hart.

“COVID-19 has had an impact on our business, but our vision and commitment are long-term,” says Bruce Ramsay, Manufacturing Director of Lovitt Technologies Australia. “Our decision to invest in these machines was driven by a combination of seeing a market for larger structures where we felt we had something to offer, and the need to do existing work more efficiently to remain competitive.

“We considered all brands with an Australian presence for each requirement, but Mazak had the product that suited our requirements best.” The jumbo-sized Mazak Vortex e-1600V/10 is a full five-axis machining centre, ideally suited for processing large, highly complex parts, such as structural components and assemblies for aerospace applications. The machine comes with a two-pallet changer that provides unattended operations and off-cycle part set-up. This simple, efficient form of automation allows operators to load, unload and inspect parts on one pallet while the machine works on the other undisturbed.

Reflecting on the Vortex investment, Ramsay comments: “The Mazak Vortex e-1600V/10 was purchased to take the next step up in size of product we could offer. It has delivered cycle time savings due to being more suited to some existing product. It has also gained us access to bid lists due to its larger size.” The Mazak Variaxis i-700 vertical machining centre features advanced multiple-surface, simultaneous five-axis machining capabilities for accurately processing parts with complex profiled surfaces in single set-ups. Paired with a Mazak Multi Pallet Pool (MPP), the system can keep running 24/7.

Ramsay adds: “The reason behind the Mazak Variaxis i-700 18 pallet MPP was to do existing work more competitively with zero set-up costs from batch to batch. The 18 pallet MPP is enabling regular lights out machining.” Both of the new Mazak machines are being used to efficiently produce complex monolithic structures such as frames, bulkheads, hinges and cranks. These products are typically difficult, with datum surfaces and various other hard-to-get-at features that must conform to stringent geometric tolerances.

At the cutting edge of aerospace

Originally founded in 1954, Lovitt Technologies Australia began manufacturing tooling for Australia’s automotive industry, and has evolved continuously, branching into fields as diverse as communications, defence and food & beverages. Today the aerospace industry accounts for around 98% of the company’s business.

Still a locally-owned family business to this day, the company operates its machining and assembly works on a company-owned site in Greensborough, Victoria, where it employs a team of more than 70 full-time staff. Complementary to this is the group’s processing facility, Electromold, which is located in Thomastown, north Melbourne, where it employs a further 40 staff.

In the commercial aviation sector, Lovitt Technologies Australia is a key supplier to Boeing, manufacturing parts of the trailing edge for the most technically advanced commercial aircraft in the world – the Boeing 787 ‘Dreamliner’. It also produces components for the 747 and 737 airliners. In addition it supplies some components for smaller commercial aircraft such as the Gulfstream business jet.

In the defence segment, the company supplies parts of the floor structure, bulkheads and the engine mounts for the Lockheed Martin F-35 Lightning II joint strike fighter (JSF), as well as parts for the Boeing F/A-18 Super Hornet and F15 Eagle fighter jets, the V-22 Osprey V/STOL military transport aircraft, P-8 Poseidon and the CH-47 Chinook helicopter.

Lovitt Technologies Australia purchased its first Mazak, a Variaxis 630-5X vertical machining centre, back in 2013. The machine is still going strong today and frequently achieves more than 5,000 hours of titanium machining per year.

Asked about the support the company has received from John Hart, Ramsay remarks: “Despite not yet having sirens on vehicles, the John Hart crew are responsive, knowledgeable, and follow through on questions and problem-solving. When you have equipment that frequently spends over 140 hours a week of actual machining, speed and knowledge in service becomes very important.”

↑ Bruce Ramsay (right) and Team Leader Ian Hodgkinson with Lovitt’s Mazak Variaxis i-700 and 18 pallet Multi Pallet Pool.

↓ Loading a job in the Mazak Variaxis i-700 and Multi Pallet Pool.