Global Manufacturing Group (GMG) has recently made significant investments in their productivity, adding three new Mazak CNC machines to their already impressive machine shop.

The new Mazak VTC 530-20 performing under high workloadsat Global Manufacturing Group

The new machines include a Mazak VTC-530/20 vertical travelling column machining centre, a Mazak VCN 530C vertical machining centre, and a Mazak HCN-5000 twin pallet horizontal machining centre.

Established in 1982, GMG is a Queensland based metal manufacturing and engineering company offering their customers exceptional quality and service by utilising the latest advancements in technology.

Located in Maryborough with a second facility in Gladstone, GMG employs 60 highly skilled staff to service a diverse range of industries including mining, defence, construction, transport, rail, medical and marine/shipping, oil and gas.

With vast experience in all facets of metal fabrication, surface coatings, and component machining GMG offers a complete turnkey solution for their customers products utilising modern world-class equipment and lean manufacturing management principles.

Richard Aylward, GMG Managing Director cited increasing demand from clients as the main driver behind the investments in the new Mazak machine tools, together with the productivity increases brought about by the newer technology.

Richard went on to say: “The latest Mazatrol Smooth conversational controllers have delivered a significant reduction in programming and set up time for us, and together with the latest technology Mazak offer in their machines, this has given us significantly reduced in process times.”

When questioned about why GMG chose Mazak, Richard commented: “We know Mazak machines very well so we didn’t need to look any further than John Hart for advice in the purchasing process. Just a good deal and short lead time was what we needed and John Hart delivered on all fronts. The training we received with each new purchase was a big benefit. Most of our operators are already well across Mazatrol so our young apprentices were able to get some really high-level one-on-one training which advanced them significantly.”

Richard concluded: “The Mazak machines continue to perform under high workloads and we always benefit from John Hart’s world class service and support. The fact that John Hart are committed to providing support for our much older Mazak machines means we would be reluctant to look elsewhere. I think the back-up service is 80% of your decision, if you cannot get service when there’s a problem, we as manufacturers are out of business. John Hart respond very rapidly to our needs, and this reliability is a big part of why we like to continue with Mazak machines.”

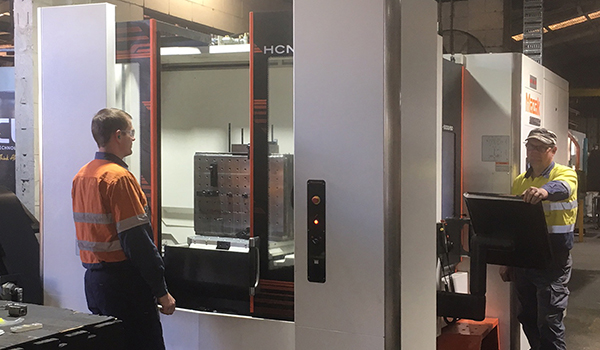

The new Mazak HCN 5000 at Global Manufacturing Group

The Mazak VTC-530/20 vertical machining centre features a fixed 2300 x 530mm table design and travelling column. The fixed table provides exceptional versatility for mounting long workpieces as well as multiple parts along the table length.

The Mazak VCN-530C vertical machining centre has a 1300mm x 550mm table and performs heavy duty machining of steel and high-speed machining of aluminium

The Mazak HCN-5000 twin pallet horizontal machining centre with 500x500mm pallets and BT50 spindle is capable of heavy machining and high speed operation.