Successful companies seldom rest on their laurels, and do not shy away from a challenge. Recently FLSmidth ABON found a new challenge in the form of a very critical operation that could not be performed on their existing multi-tasking machines. The reason was not only the extremely complex technology involved but also the lack of a successful precedent in producing dimensionally correct, geometrically true gears of various kinds on a general purpose multi-tasking machine.

The FLSmidth ABON brand has been synonymous with reliable, heavy-duty mining equipment for more than 50 years and combined with FLSmidth’s 135 years of experience provides customers with increased output and quality, reduced total cost of ownership and optimized productivity.

FLSmidth ABON is a leading manufacturer of Low Speed Sizers, Roller Screens and Chain Feeders for the worldwide mining industry. Their products are mainly used in mining operations of mineral resources such as a coal, iron ore and copper and also used in various industries such as quarry applications, smelter applications, fertilizers, or cement plants.

To stay competitive in the global arena FLSmidth ABON have been at the forefront of manufacturing technology. They have been no stranger to the power, versatility and user friendliness of Mazak multi-tasking machines having used them over a decade to produce complex high-quality parts in a minimum number of operations, and they have been highly successful in utilizing the Mazatrol programming system to achieve this.

Successful companies seldom rest on their laurels, and do not shy away from a challenge. Recently FLSmidth ABON found a new challenge in the form of a very critical operation that could not be performed on their existing multi-tasking machines. The reason was not only the extremely complex technology involved but also the lack of a successful precedent in producing dimensionally correct, geometrically true gears of various kinds on a general purpose multi-tasking machine.

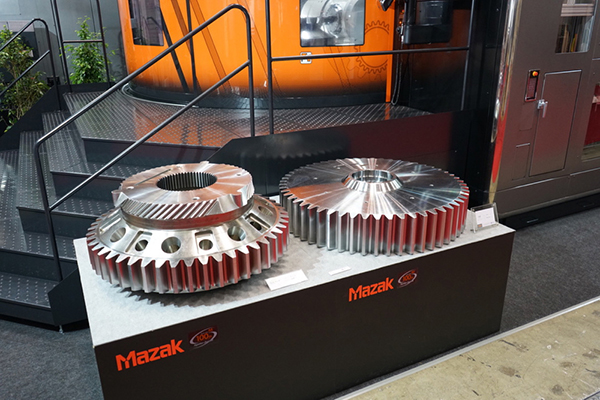

FLSmidth ABON had been a proud customer of John Hart and Mazak for a long time and they were no stranger to the technology and support John Hart offers. Owing to their past experience FLSmidth ABON decided to put their faith in John Hart and Mazak once again and embarked on a journey, the successful conclusion of which has made them a part of the Australian engineering industry folklore and a jewel in Victorian manufacturing industry’s crown. John Hart, Mazak and FLSmidth ABON worked in partnership utilising Mazak’s Smooth Gear Machining software suite to machine external and internal gears by using techniques of gear hobbing, skiving, shaping and milling. Mazak's Smooth Gear Machining software allows for the conversational input of project parameters on the Mazatrol SmoothX CNC machine controls, making it easy for virtually any operator to handle gear-related projects with Mazak Smooth Gear Milling, Hobbing and Skiving functions to machine parallel-axis O.D., I.D. and spline-type gears.

These advanced gear-making applications require no 3D models or programming steps. Instead, operators simply enter workpiece parameters into a conversational dashboard interface and the software creates the necessary machine instructions. Operators can then modify tooth profiles and leads, set up edge tapers, and take advantage of Mazak Smooth Gear Machining’s sub-micron profiling capabilities.

FLSmidth ABON had been programming on the machine utilizing the Mazatrol conversational programming system however a cam system was also required to complement Mazatrol. Their objective to have flexibility and failsafe processing alternatives made them search for a reliable high-performance cam system.

As the authorised Australian reseller of hyperMILL, John Hart introduced the software to the company.

After looking at a few CAM systems, FLSmidth ABON realized hyperMILL is the leading and best CAM software among all and selected hyperMILL due to its cutting-edge technology and high level of John Hart support. No other systems had features that would match hyperMILL, which has the best post processors and dynamic collision checking.

For example, surface quality, time savings, tool life, machine performance, increased efficiency. Fast, reliable and collision free tool paths along with error free G code output has been the main advantages. These factors contribute towards increased productivity, increased efficiency, better quality, better tool life and smoother machine operation.

The combination of machine tool capability, processing design and hyperMILL, in-process time was reduced. hyperMILL MAXX Machining proved to be helpful in reducing finishing and roughing times.

To have synergy between CAD, CAM, post processor and the machine had been one of the key selection criteria. FLSmidth ABON realized that the lack of even one of these features could set them back a long way. hyperMILL together with the ongoing and reliable technical support from John Hart engineers had them assured about successfully fulfilling their manufacturing requirements.

![]() Download the article as it appeared in AMT Magazine Jun 2020207.14 KB

Download the article as it appeared in AMT Magazine Jun 2020207.14 KB