The CAM solution for high requirements of blow molding

Excellent high-gloss surfaces and flawless transitions in all details are important quality features of blow molds. A good CAM solution supports you to meet the high requirements.

hyperMILL has been setting standards in the mold making industry for over 25 years and also offers a complete solution for blow mold manufacturing. From automation processes to data import to efficient programming to NC-Code simulation. Regardless of whether it is molds for the beverage and food, pharmaceutical, cosmetics or household goods industries – with hyperMILL you always have the right solution to fully meet the high requirements. Thanks to customer-oriented development and close collaboration with well-known machine tool and cutter manufacturers, we ensure that hyperMILL can continue to improve your processes in the future.

Specially developed CAM strategies such as 5-axis radial machining and other innovative technologies make hyperMILL the best choice for blow mold production. This way you are always one step ahead in the demanding competition of modern industry.

5-Axis Machining: Bottle Mold

hyperMILL offers strategies and functions to manufacture high quality bottle and blow molds. This demo part was machined out of an aluminium block.

Features

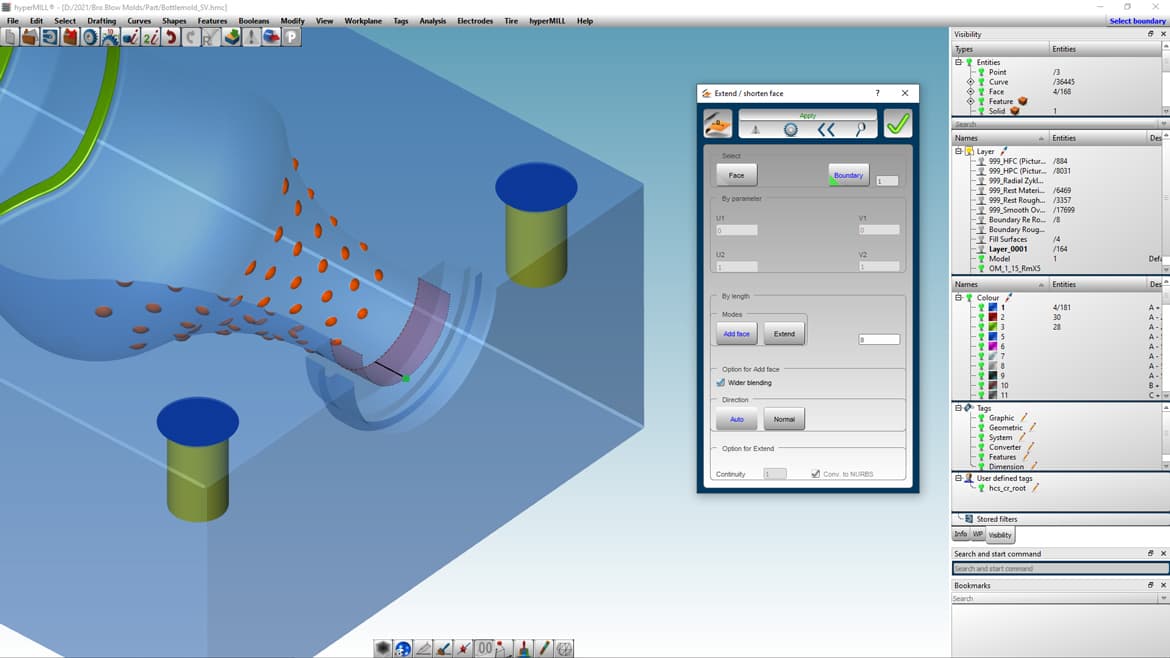

Own CAD software (formerly hyperCAD-S)

- Interfaces to all relevant CAD systems

- Comprehensive analysis tools

- Intuitive design functions

- “CAD for CAM” functions (Closing holes, Extending surfaces…)

- Possibilities for documentation and creation of drawings

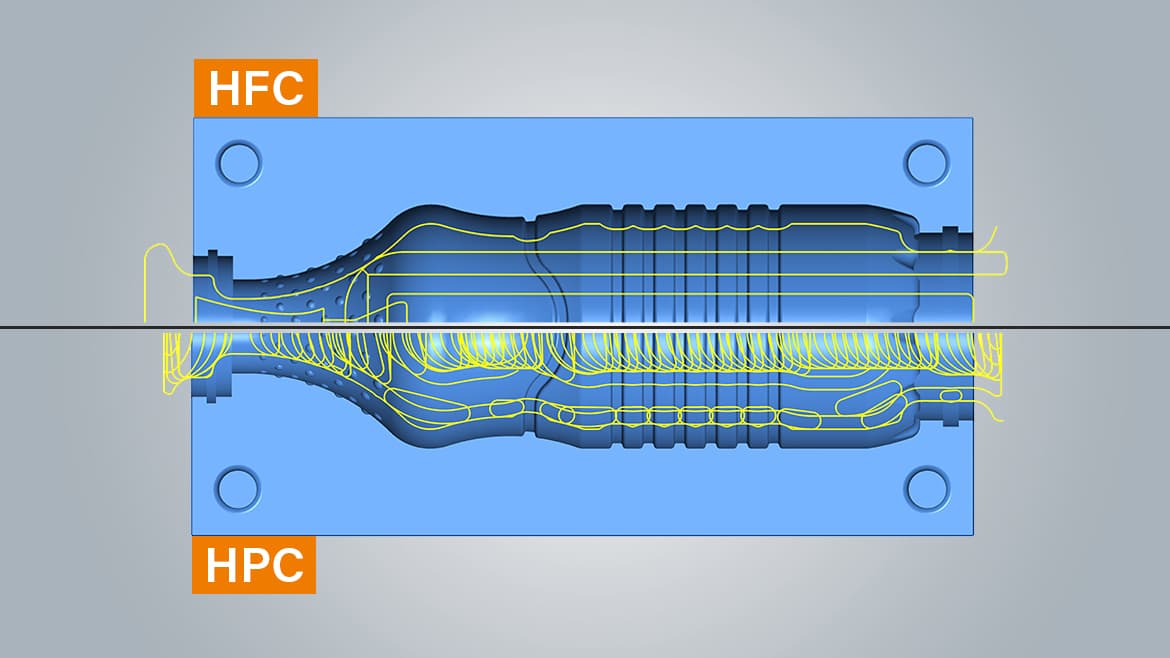

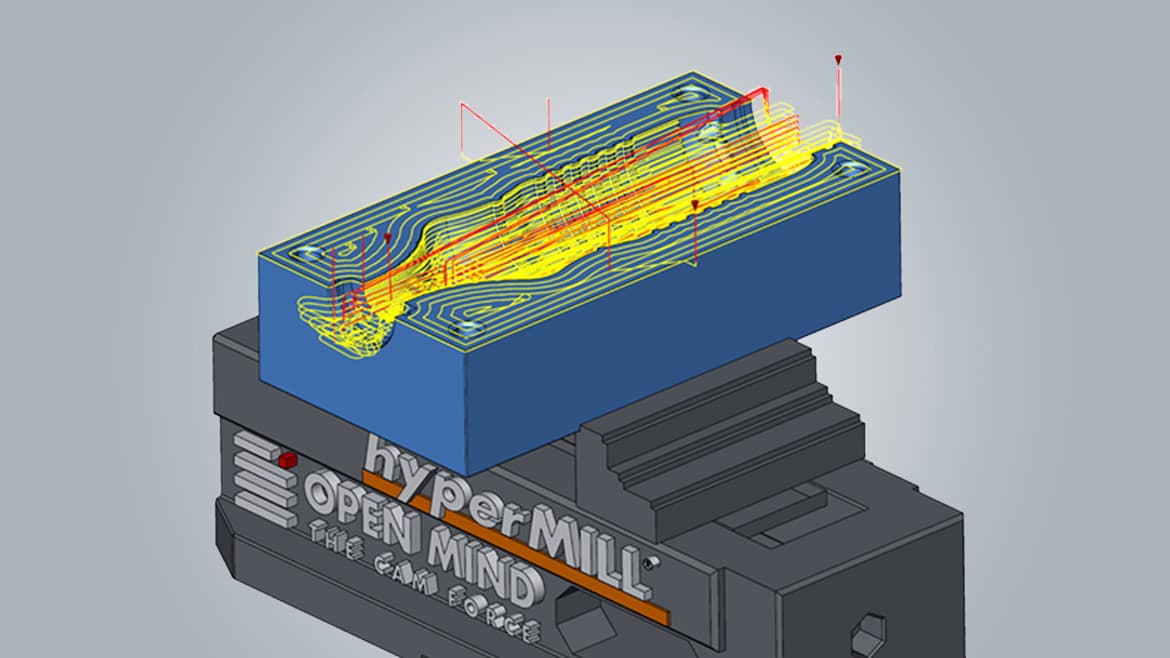

Efficient roughing strategies

- Fast, stock based toolpath calculation

- Efficient rest material roughing

- Modern roughing strategies like HPC, HFC and more

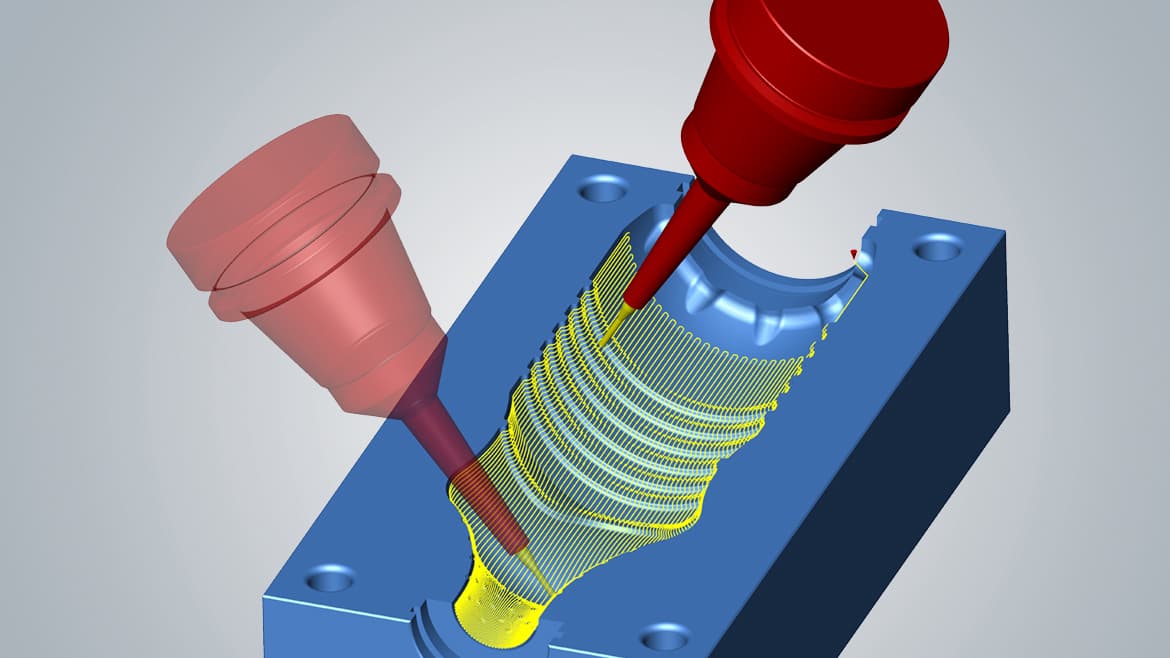

Precise rest material finishing

- Efficient contour parallel toolpaths

- Short machining times

- Available as a 3D or 5-axis strategy

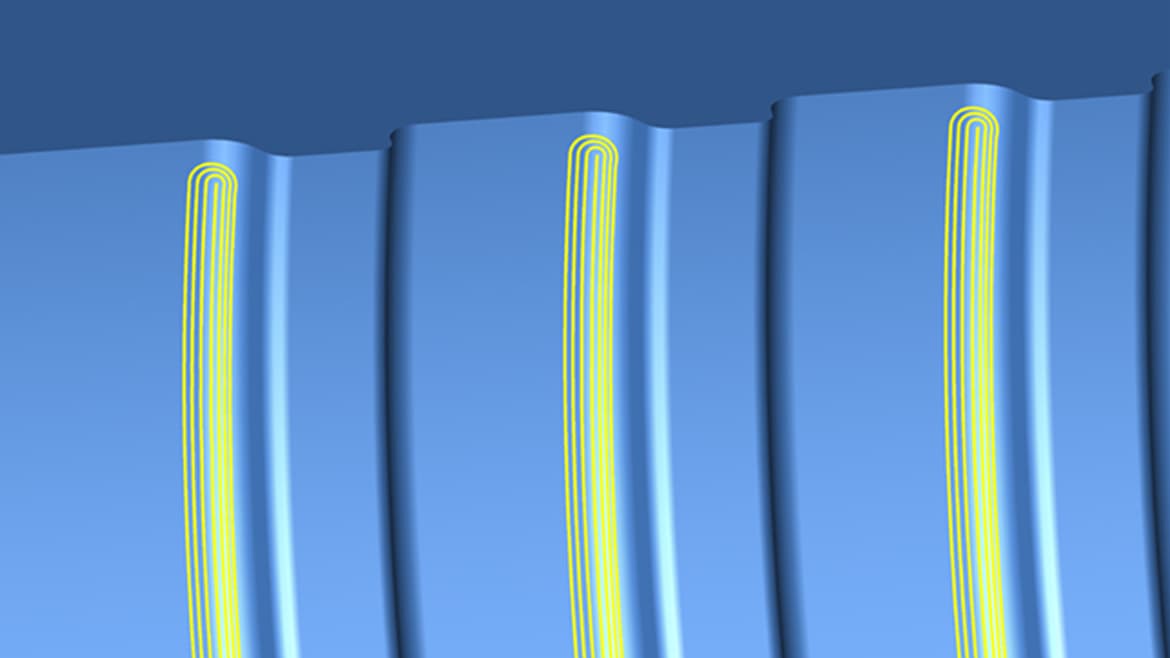

Specially developed finishing strategy: Radial Machining

- Radial projection method

- Precise calculation on the CAD surfaces

- Very short calculation time

- Constant 3D path infeed

- Smooth overlap for perfect transitions

- Intelligent inclination options

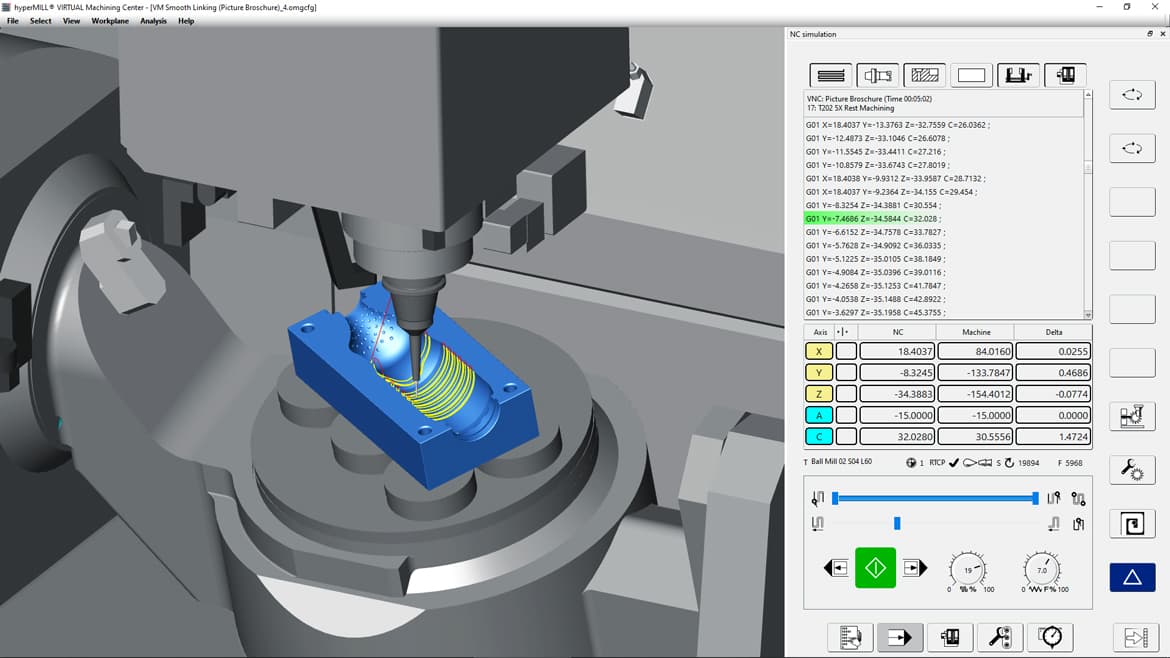

Safe and reliable NC-Code Simulation

- Simulation of real NC codes

- Analysis functions for toolpaths

- Automatic NC code optimization

- hyperMILL CONNECTED Machining

Unique Automation possibilities

- CAD function automation

- CAM function automation

- User-controlled and interactive automation

- Code programming skills are not required

- Up to completely automated CAD/CAM processes

Advantages

- Powerful CAD Platform

- Efficient Roughing Strategies

- Precise Finishing Strategies

- Real NC code Simulation

- hyperMILL AUTOMATION Center

Gallery

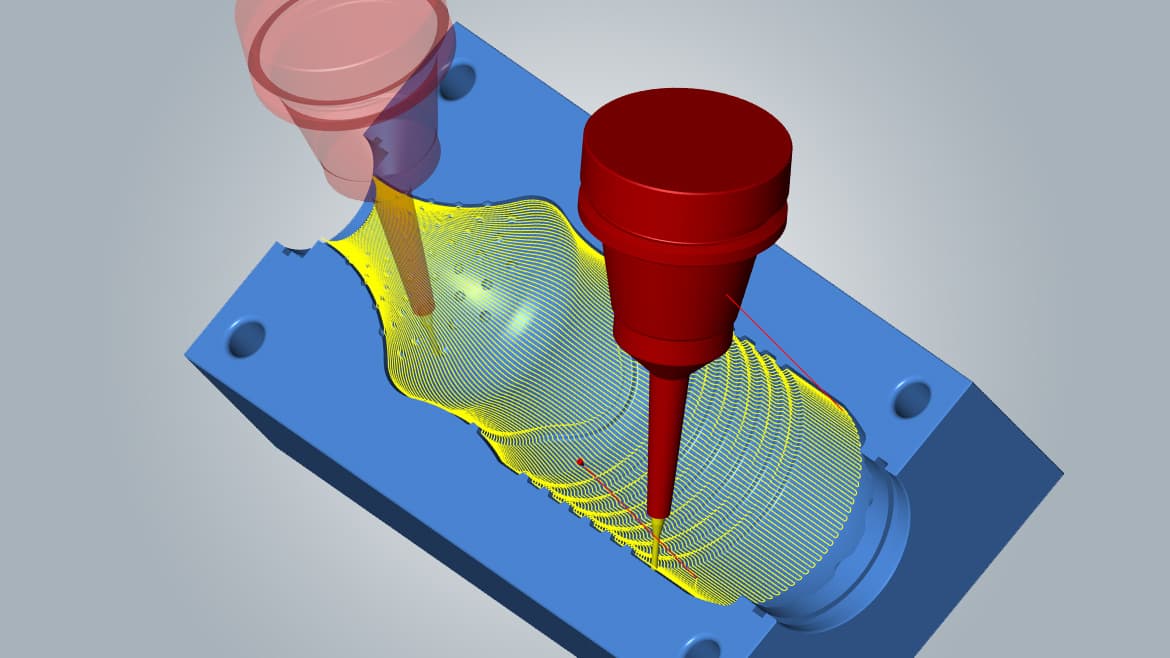

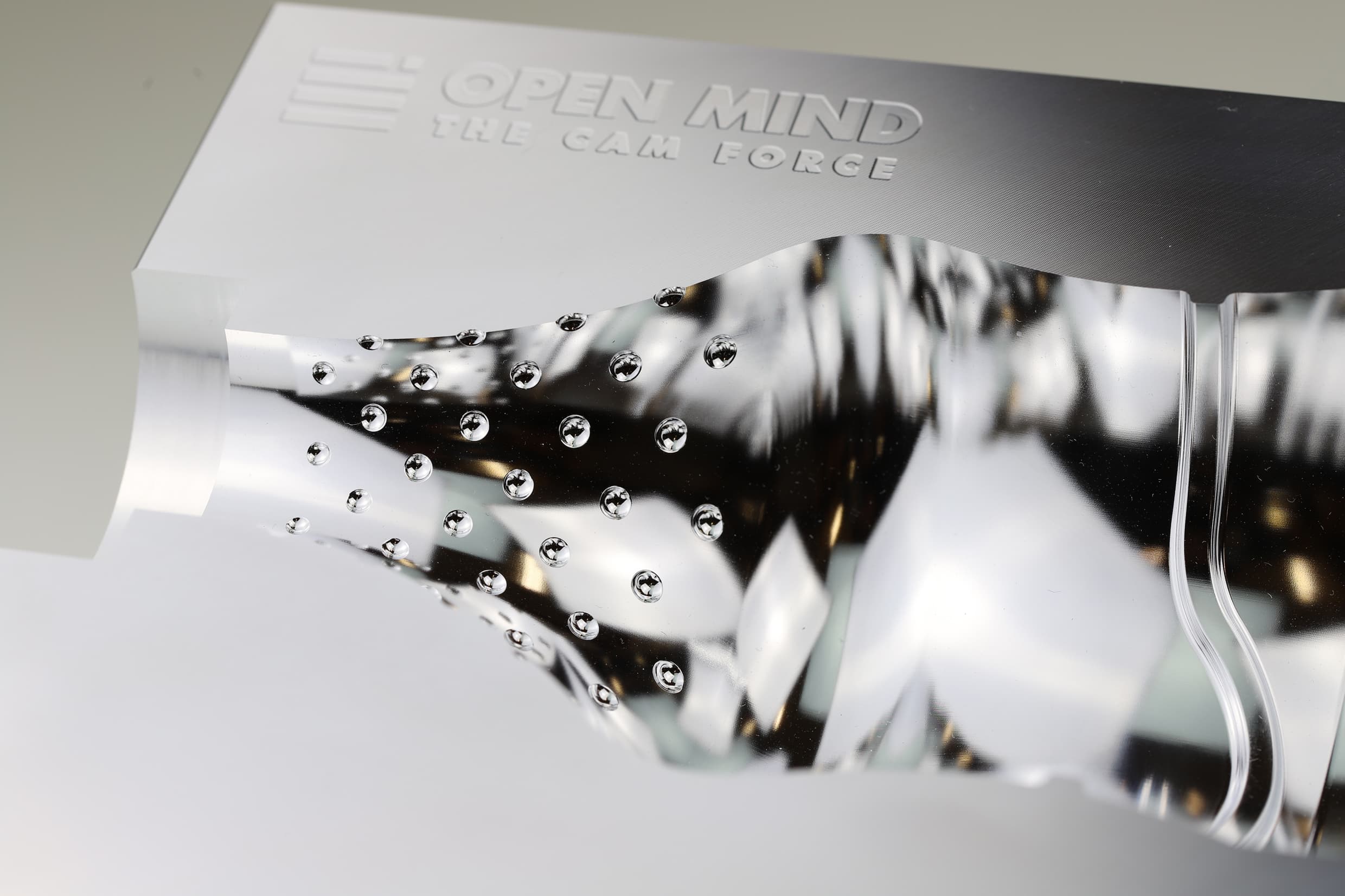

High-gloss machining of a bottle mold with the special 5-axis radial machining strategy

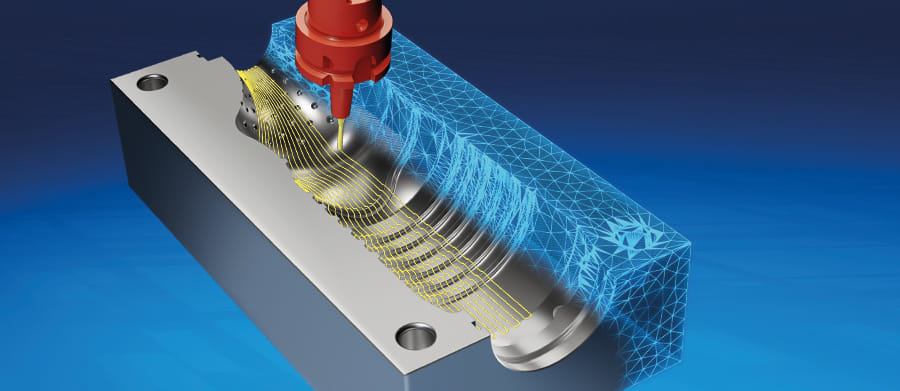

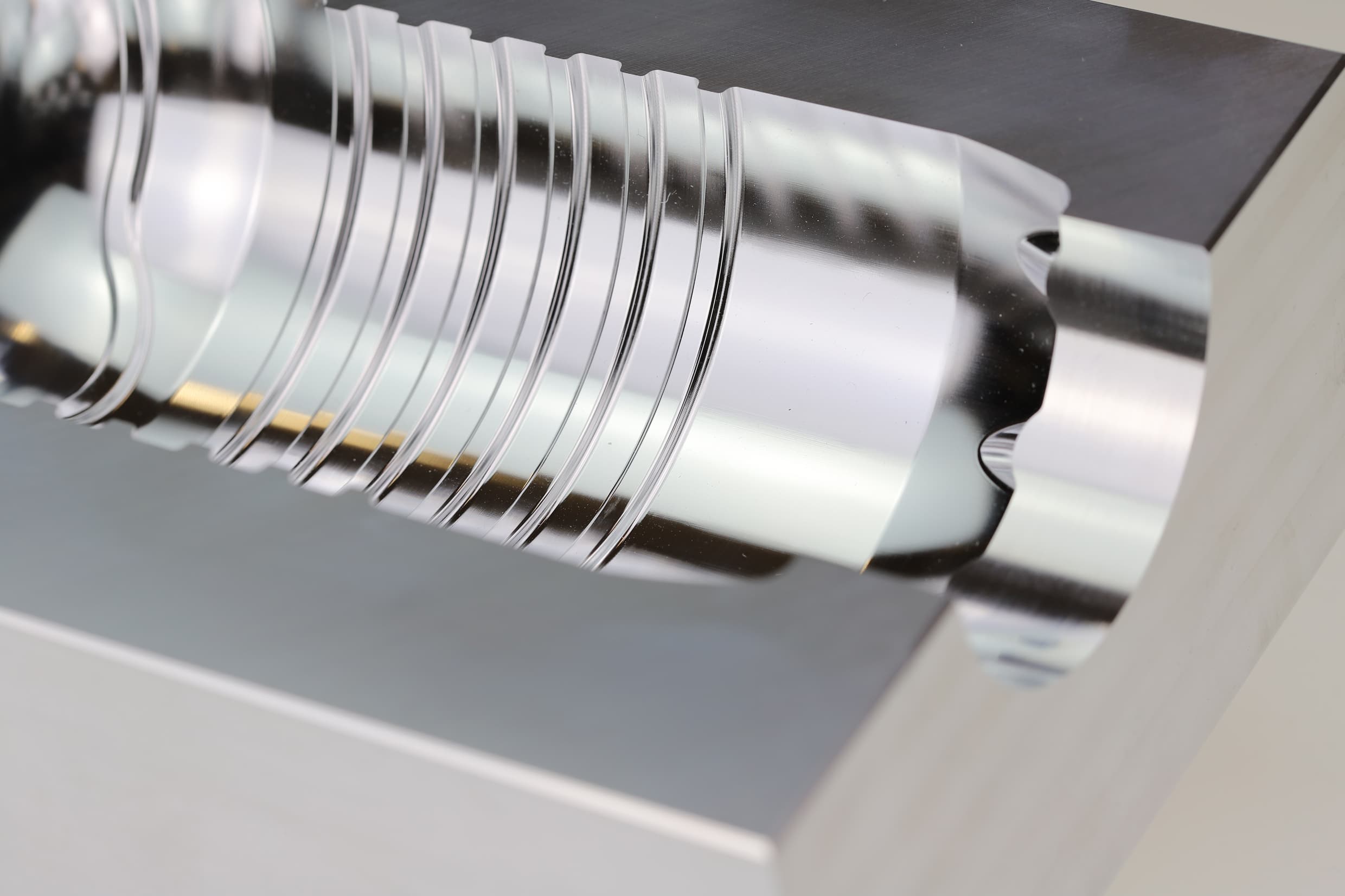

Mold insert finished with a barrel cutter strategies

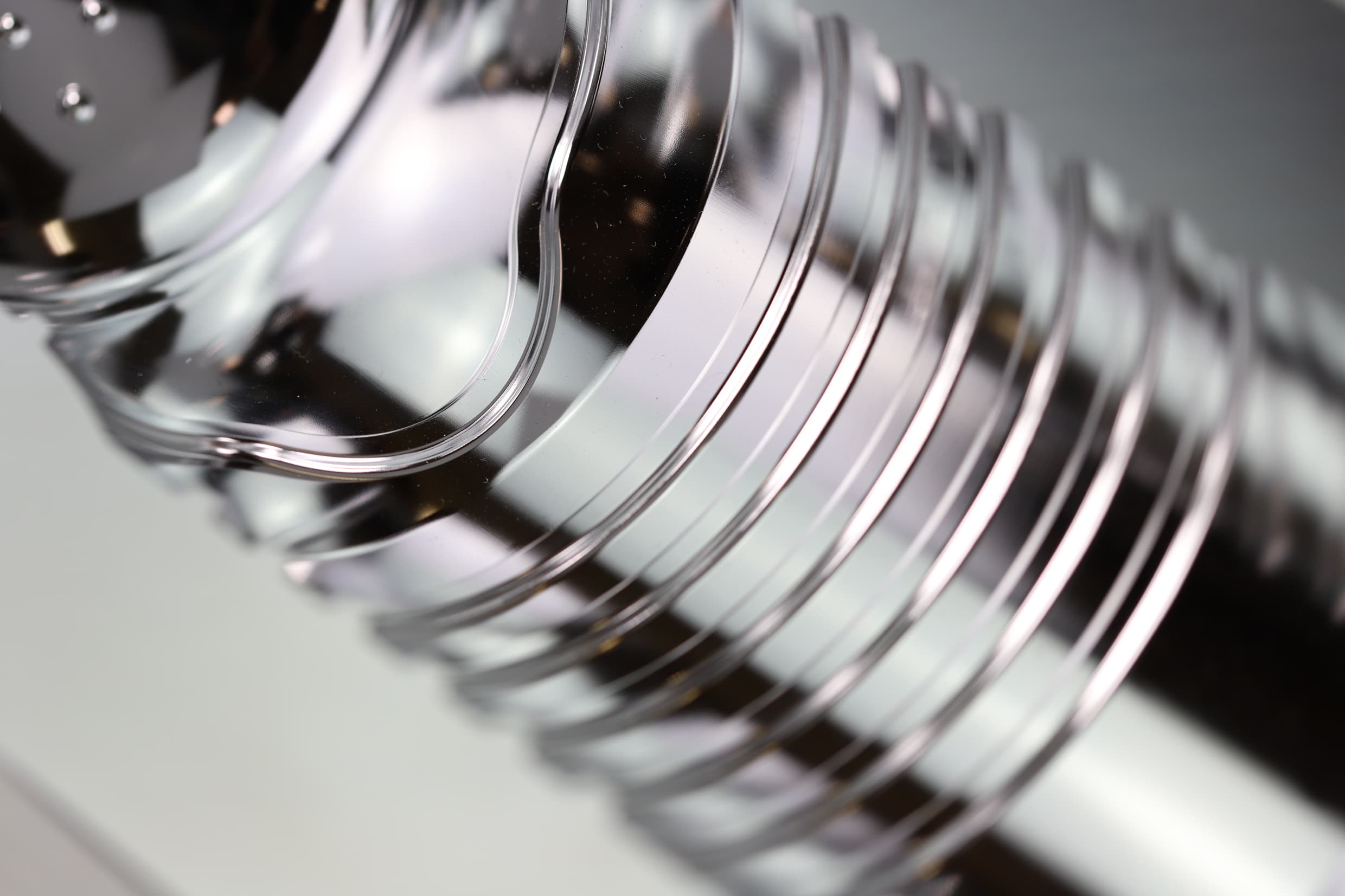

Precision machining of a hardend part with 55 HRC

Blow Mold Machining Package brochure

![]() Download the Blow Mold Machining Package brochure1.03 MB

Download the Blow Mold Machining Package brochure1.03 MB

Complete CAM Solution for Efficient Blow Mold Machining.