The Tube package

5-axis CAM software: The Tube package from OPEN MIND provides optimized milling strategies for complete machining.

This 5-axis tube machining package is for intake and exhaust tubes for engines as well as pipe inlets and outlets for pumps and condensers. It is possible to continuously machine strongly undercut geometries in one operation on the basis of the simplest guide curves. Since no special demands are made of the data model, trimming, closing of gaps and surface feedback can all be eradicated. This easy-to-use package allows the user to achieve quick results without time-consuming tests. The proven collision check and avoidance system ensures safe 5-axis milling operations.

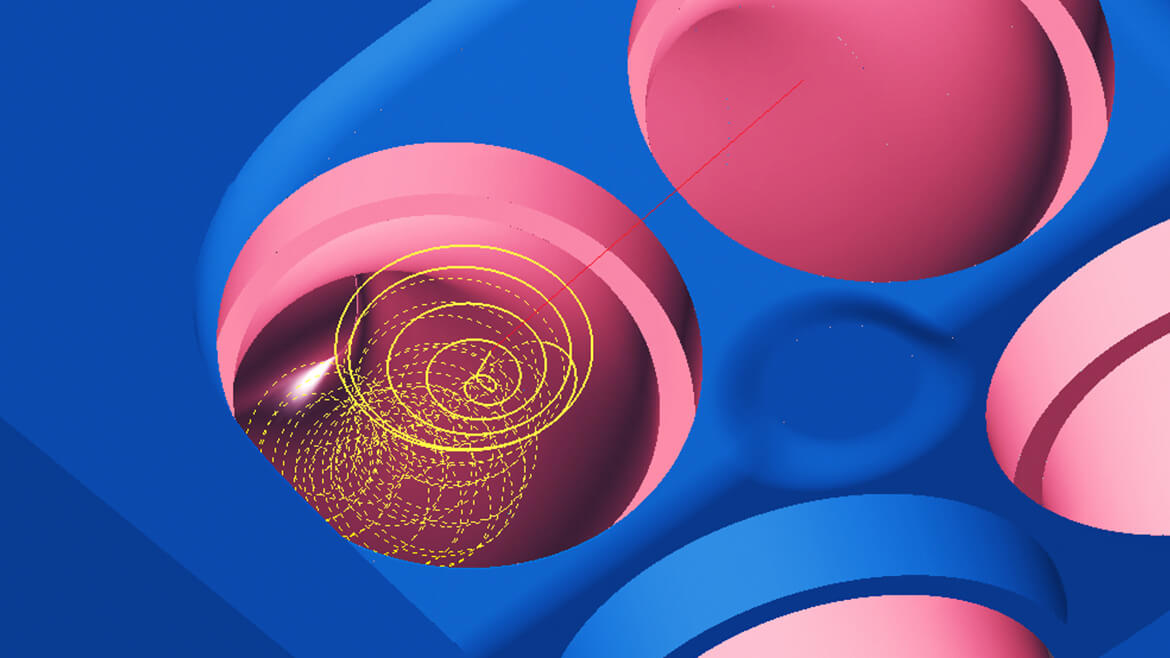

5-axis tube roughing

With this strategy, the tube is milled in a continuous machining process from stock. This 5-axis simultaneous strategy is an effective alternative to machining with several axes in fixed positions. There is a spiral infeed to the bottom and work is executed on the plane. Stock removal can occur from the outside to the inside as well as from the inside to the outside.

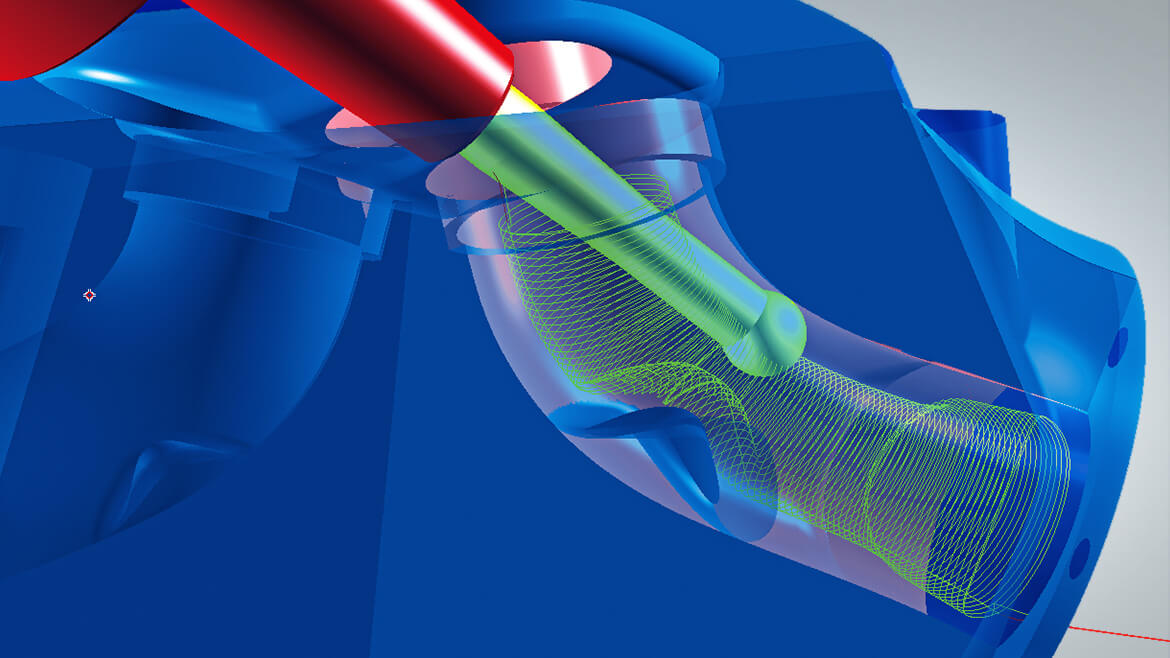

5-axis tube finishing

With this strategy, the tube is finished with a spiral or parallel toolpath. The spiral toolpath creates a seamless, high-quality surface. With parallel machining, it is possible to avoid unnecessary movements of the rotary axes.

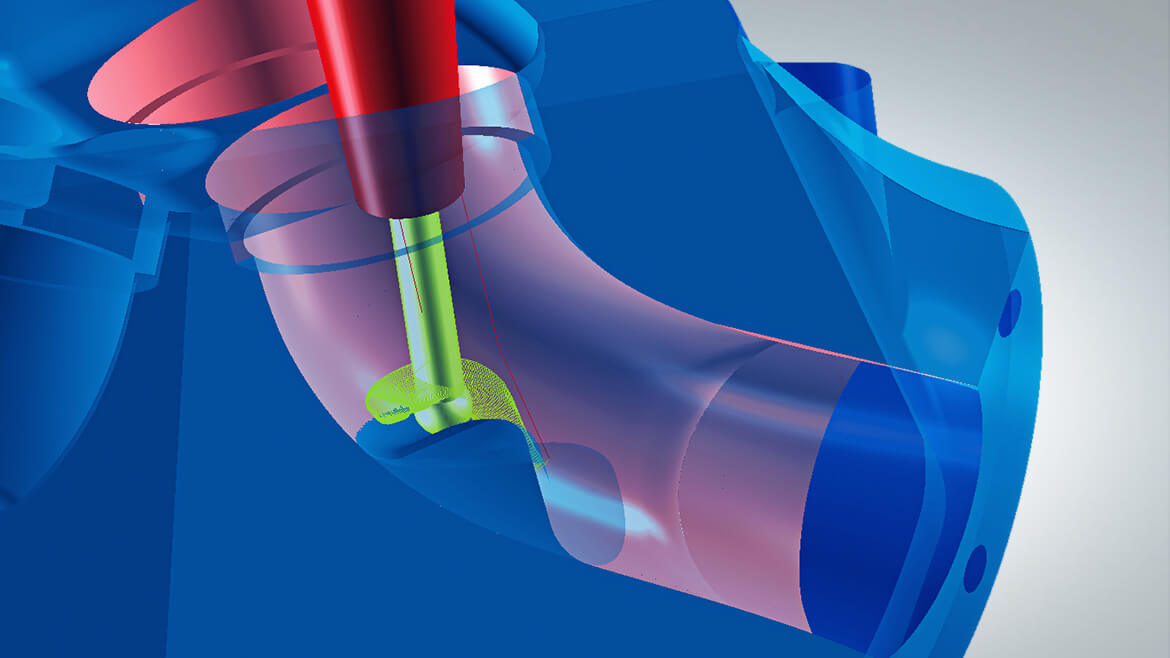

5-axis tube rest machining

With this strategy, rest material areas are machined in either a spiral or parallel movement. The areas to be machined are described by a reference curve. The machining width can be limited by defining a value symmetrical to the reference curve.

Tube Package brochure

![]() Download the Tube Package brochure933.46 KB

Download the Tube Package brochure933.46 KB

Quickly programmed. Easily milled.