The Tyre package

5-axis CAM Software: The Tyre package from OPEN MIND offers automated pitch repetitions for more efficiency.

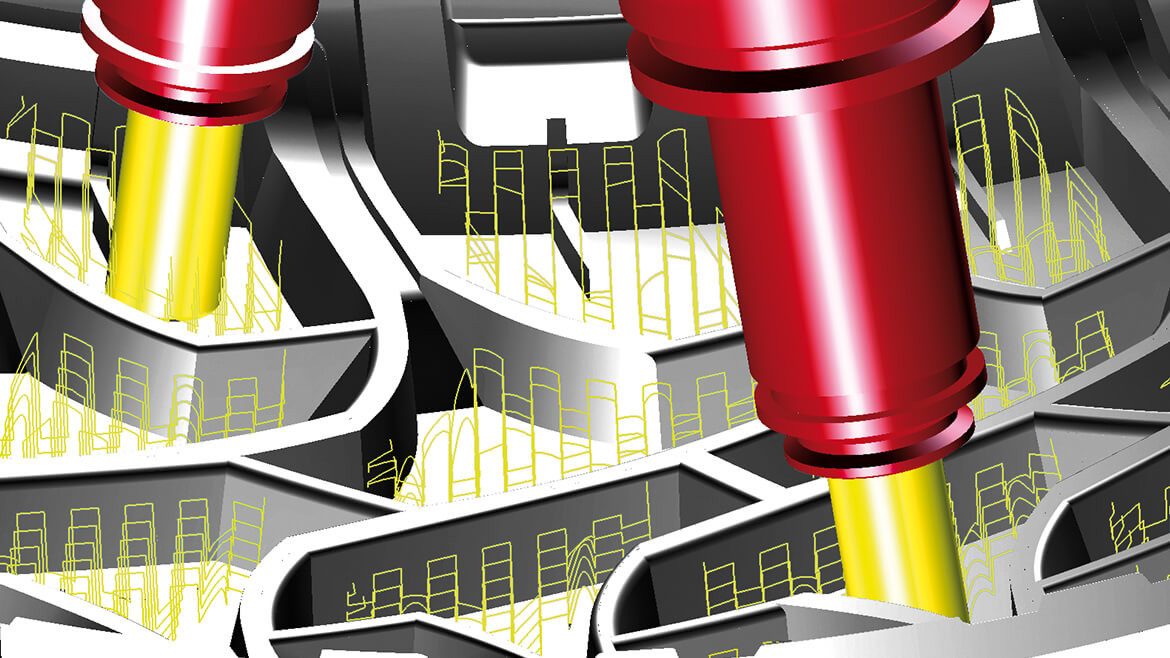

Whether using positive or negative molds – the Tyre module mills tyre molds more economically than ever before. Automated milling strategies and special functions guarantee a simplified and efficient programming process. For example, sipes and stone ejector functions, as well as other details, are facilitated by a recurring arrangement of identical tire sections that is usually defined with a tyre clock. Each area (pitch) must therefore be programmed only once.

The tyre utility also copies the tool paths to the relevant positions in the tire. In doing so, the automated segment generation trims the tool paths that go beyond the segment limit. Optimised milling paths considerably reduce the machining time.

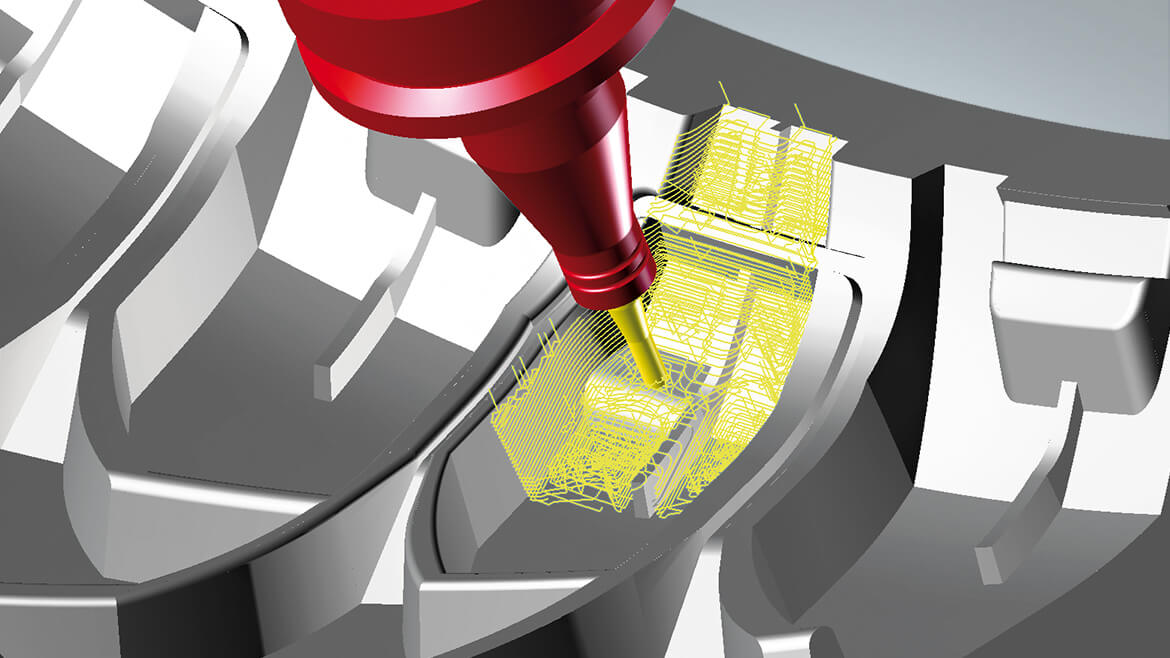

5-axis top milling

In addition to rapid finishing with endmills and bullnose cutters that allow large stepovers, this cycle can also be used for optimized roughing on pre-turned stock. The tool follows the surface curvature ensuring more consistent remaining material on the floor and the profile walls.

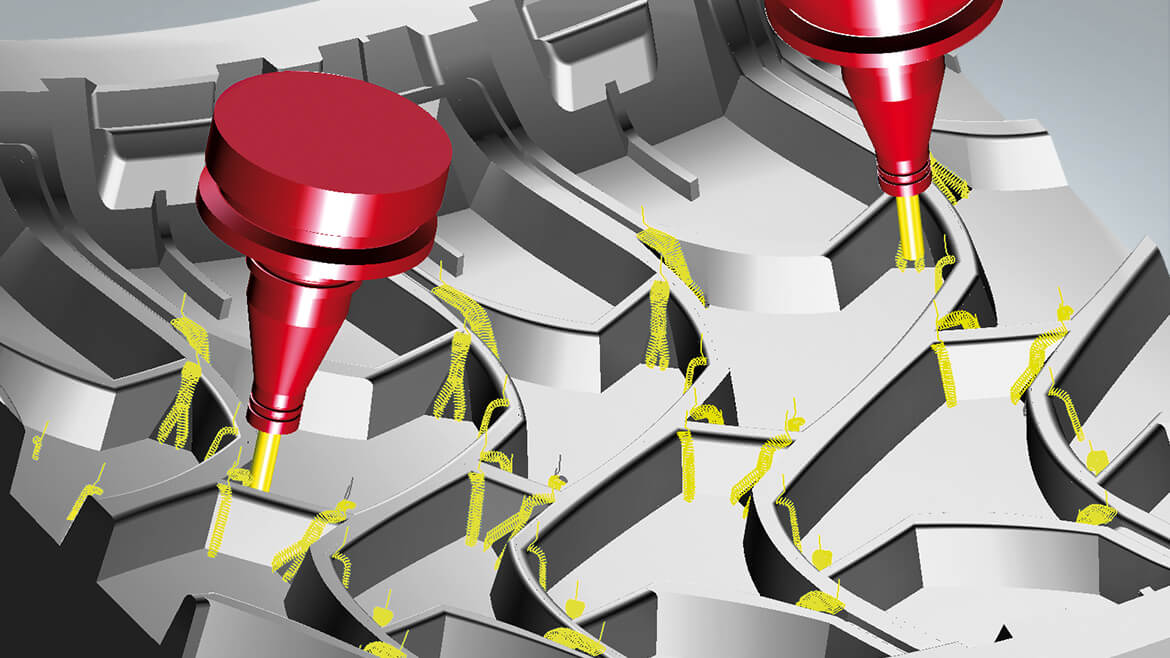

Arbitrary stock roughing

This ensures that fine points are effectively worked. The exact tracking of remaining material helps to avoid redundant movements and guarantees a high degree of process reliability when using slender tools. The individual machining operations can be performed in any direction with various setups.

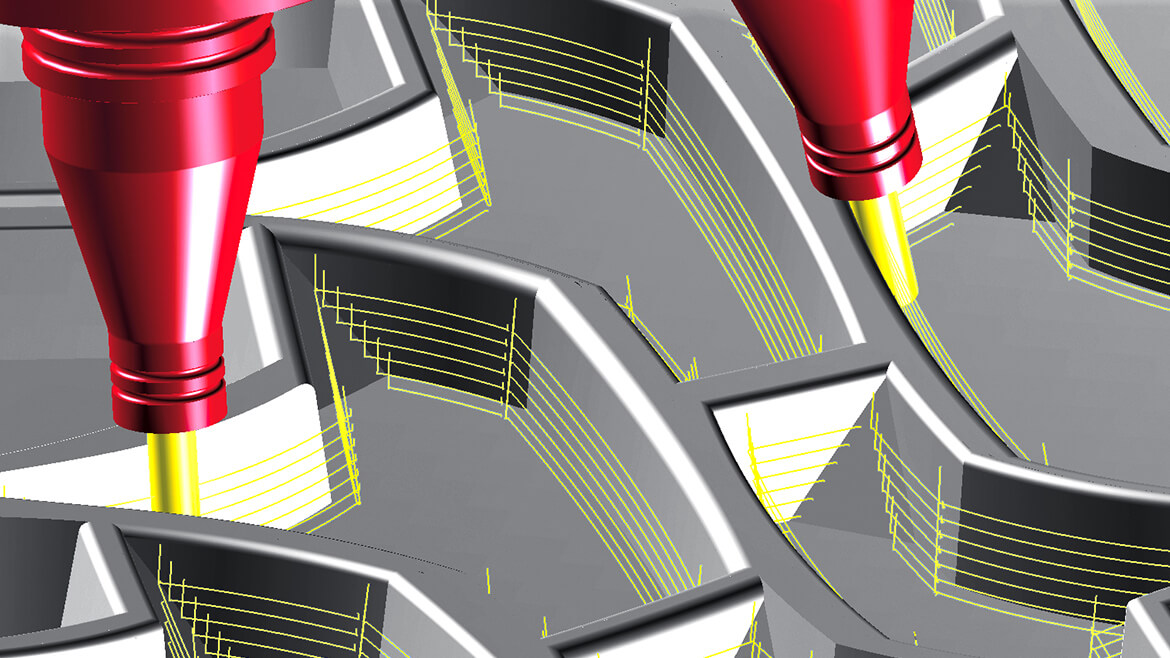

Optimized 5-axis swarf cutting

Swarf cutting permits more effective machining of ruled surfaces. This cycle makes the milling of profile flanks and sharply angled inner corners very easy. Tapered tools can also be employed. The definition of milling and stop surfaces protects neighboring surfaces.

5-axis rest machining

The sharp edges of the tire molds can be machined precisely with slender tools without having to be reworked. This cycle recognizes all rest material areas, even in undercuts. The machining is performed on multiple segments in one collision-free operation. In addition, this cycle generates especially smooth movements.

5-axis contouring

For 5-axis reworking of edges and efficient programming of sipes, this cycle ensures contours with different tool positions are machined in one step. hyperMILL combines the individual machining operations automatically with optimzed toolpaths and collision-free tool movement.

Tyre Mold Package brochure

![]() Download the Tyre Mold Package brochure2.91 MB

Download the Tyre Mold Package brochure2.91 MB

Taking tyre machining to the next level.