Powerful CAM Solution for Lasting Company Success

CAM software primarily supplies perfect NC programs for machine tools. But not all CAM is the same: There are often considerable differences in the machining strategies, programming required, actual machining times, and surface qualities.

Discover the power of hyperMILL – the innovative CAM software from OPEN MIND. Find out how important it is to be able to integrate a CAM system into existing manufacturing processes in order to drive digital processes forward in your company – because this is the only way to achieve sustainable competitiveness.

What is CAM software?

CAM stands for computer-aided manufacturing.

CAM software is used to develop programs for a variety of CNC machines such as milling and turning machines, for example, or machines for cutting edge machining or additive manufacturing.

CAD and CAM – hand in hand

No CAM system can get by without CAD. The CAD software displays the 3D model and passes all necessary information about the component to the CAM system. Additional modeling aids for programming or changes to the CAD model are part of the daily routine of a CAM user.

With the CAD functionalities software in its hyperMILL software, OPEN MIND offers a powerful CAD solution (formerly hyperCAD-S) specifically for the requirements of CAM programmers. This is CAD for CAM! Are you keen to integrate hyperMILL CAM software into your existing CAD system? OPEN MIND also offers solutions for this in the form of CAD integrations for the two leading systems Autodesk Inventor and SOLIDWORKS.

hyperMILL CAD for CAM

OPEN MIND developed its own CAD basis (formerly hyperCAD-S) that is perfectly tailored to its hyperMILL CAM software. The CAM specialist is fully focused on the needs of NC programmers.

hyperMILL for SOLIDWORKS

SOLIDWORKS 3D CAD software and hyperMILL for SOLIDWORKS – the CAM program as a powerful CAD integration – work together to speed up design and manufacturing processes. This ensures products reach the market faster.

hyperMILL for Autodesk Inventor

Autodesk Inventor CAD software and hyperMILL for Autodesk Inventor – the CAM program as a powerful CAD integration – the two make a perfect team when it comes to significantly speeding up design and manufacturing processes.

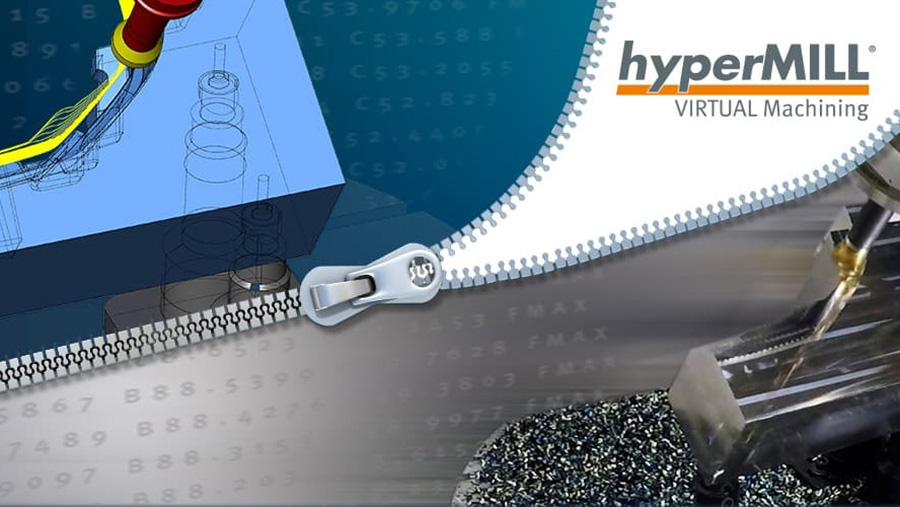

NC code fuels the machine

Generating the NC code is one of the most important tasks of a CAM system. The virtual toolpaths are converted into real movements for the CNC machine, and an NC program is created.

The important thing here is to adapt the NC code to the individual properties of each machine. This is provided by OPEN MIND’s unique postprocessor technology.

In keeping with the motto “trust is good, control is better”, the machine movements must first be simulated on the computer. hyperMILL VIRTUAL Machining represents an exception here. While other systems use internal CAM data for simulation, OPEN MIND uses the generated NC code to simulate the movement sequences precisely – to ensure the greatest degree of safety during manufacturing.