Modern Manufacturing: Digitalisation Starts with CAM.

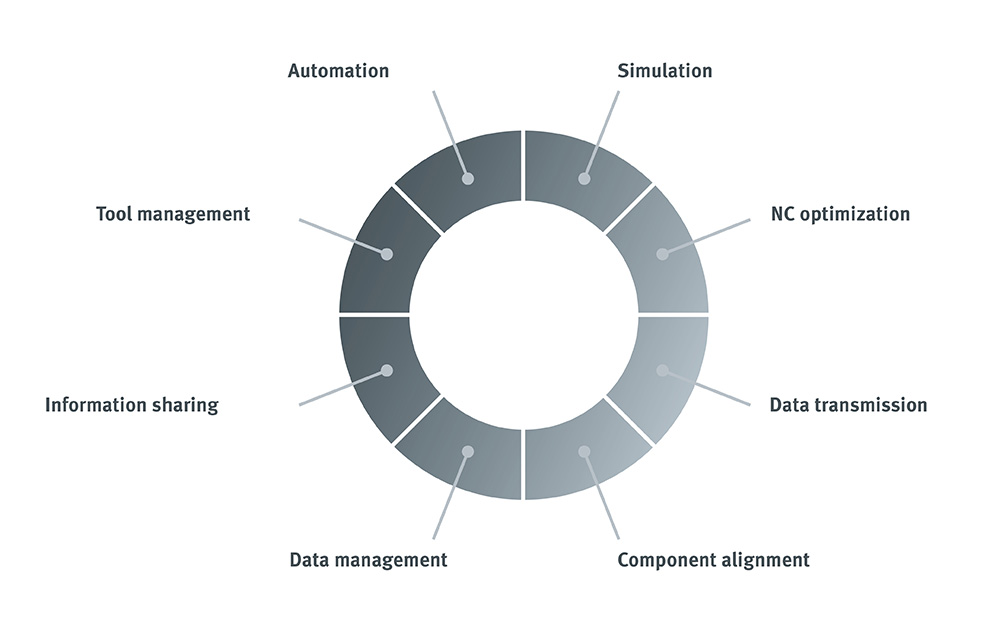

The CAM system is set to play an increasingly centralized role in digitalisation strategies at manufacturing companies in the future. This is the point that OPEN MIND Technologies AG is emphasising at the moment. Connecting the systems used throughout the production process is a core requirement for CAM systems to take on this role.

The company behind the hyperMILL CAD/CAM suite further underscored this point through its acquisition of MES specialist Hummingbird Systems GmbH in early 2022. Integration of CAM and MES is just one example of the communication capacities that will be required by CAM systems in the future.

“Everyone is talking about digitalisation, Industry 4.0, and the Internet of Things. Small to medium-sized enterprises with machining operations want to know how they can keep up,” says Michael Förster, Senior Product Marketing Manager at OPEN MIND Technologies AG. “With NC code generated from CAD data, each of these companies has a digital process already in place. This can serve as a starting point, with connectivity having a key role to play.”

Based on OPEN MIND’s experience, the comprehensive digitalisation strategies of large companies are in many cases too broad for SMEs. A more suitable approach would be to seek out digitalisation solutions in steps, starting with the CAD/CAM system. There are different strategies available based on the company’s IT landscape: linking the process in and around CAD, CAM, and NC data to a product lifecycle management (PLM) system or manufacturing execution system (MES). This enables the integration of a tool management system, making CAD data accessible company-wide, and using bidirectional communication with the machine controls.

Digital production environment: networking with hyperMILL delivers benefits in many areas.

Advanced processes

According to OPEN MIND, the flow of data from design to production can help optimise the process through better networking. Simulations based on real NC codes and advanced optimisation processes are made possible based on bidirectional communication between the CAM system and machine controller.

hyperMILL – your crucial piece for your connected manufacturing environment!

The innovative CAD/CAM solution hyperMILL offers you technologies for forward-looking, intelligent connection of digital and analog processes. Pioneering digitalisation solutions provide you with the right tools to increase efficiency and sustainably optimise your manufacturing capacities. With hyperMILL, you remain flexible across all systems throughout the company, laying the foundation for trend-setting and connected manufacturing!

CAM system for a connected world

OPEN MIND provides answers to the question of “what role the CAD/CAM system will play in an increasingly connected world” in this white paper

OPEN MIND provides answers to the question of “what role the CAD/CAM system will play in an increasingly connected world” in this white paper