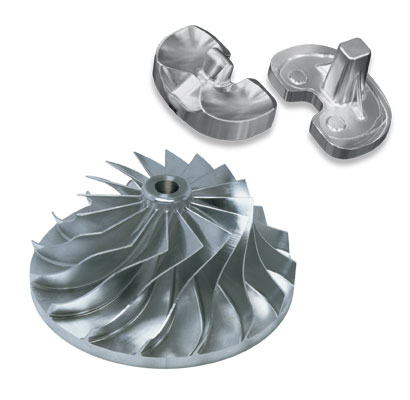

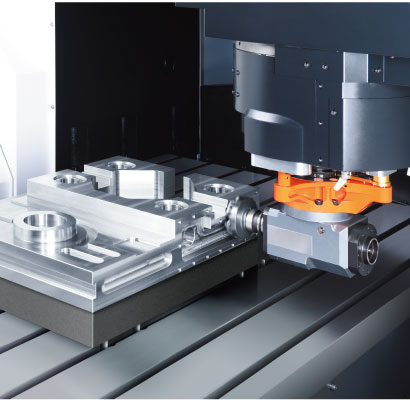

Mazak Vertical Machining Centers offer a wide range of specifications including the machine equipped with #40 spindle for high-speed cutting, and with #50 spindle for high-torque, heavy-duty cutting.

What is Vertical Machining?

Vertical Machining, also known as milling, relies on rotary cutters to remove metal from a workpiece. Vertical machining occurs on a vertical machining center (VMC), which employs a spindle with a vertical orientation. With a vertically oriented spindle, tools stick straight down from the tool holder, and often cut across the top of a workpiece.

The benefits of Mazak Vertical Machining Centers

- 3-, 4- and 5-axis capabilities for infinite possibilities as to the part shapes you can process

- Temperature stability through integral cooling

- MX Hybrid Roller Guides provide durability and reliability for long-term accuracy

- On-board probing for part location and feature inspection with the cutting cycle

- User-friendly CNC controls simplify programming and increase productivity

- Pallet changers that increase spindle utilization and reduce part cycle times