Mazatrol TWINS

![]()

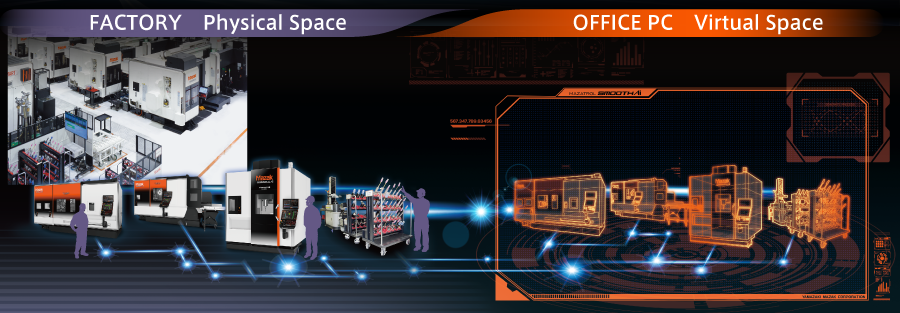

Virtual TWINS of machine equipped with the Mazatrol SmoothAi

Advanced digital technology for manufacturing

Virtual machines in your office duplicate the operation of machines on your factory floor. Available software can be used together with machines equipped with the Mazatrol SmoothAi CNC to substantially increase the efficiency of your production.

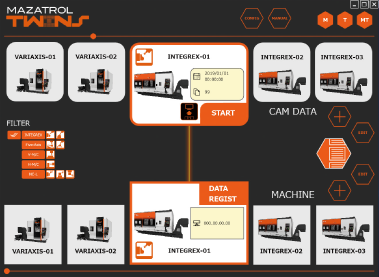

Smooth PROJECT MANAGER

Smooth PROJECT MANAGER

File management

Convenient management of data required to execute machining programs.

- Tool data

- Fixtures

- Coordinate system

- Parameters

- Workpiece 3D model

Project data synchronization

Project data is synchronized between machines and Smooth CAM Ai and other CAD / CAM software. Data produced by virtual machines are output to machines equipped with the MAZATROL SmoothAi CNC for fast setups.

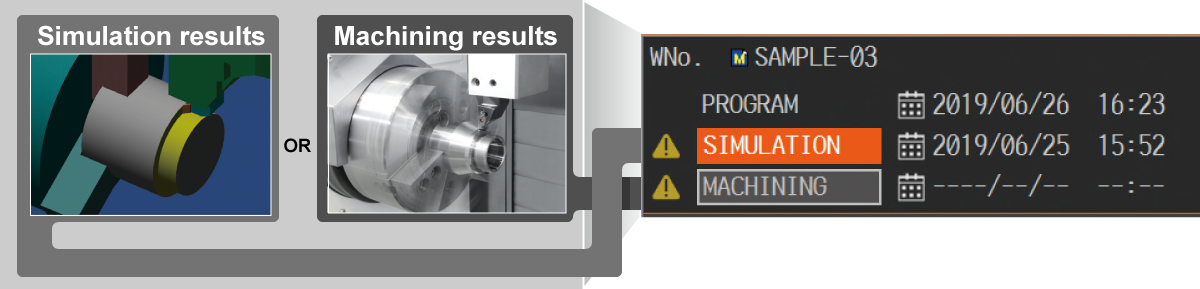

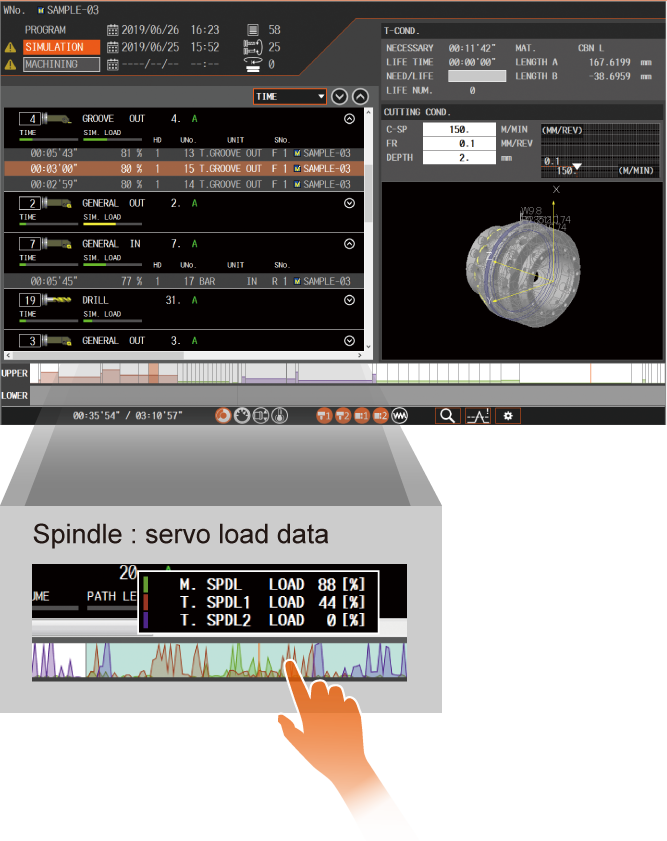

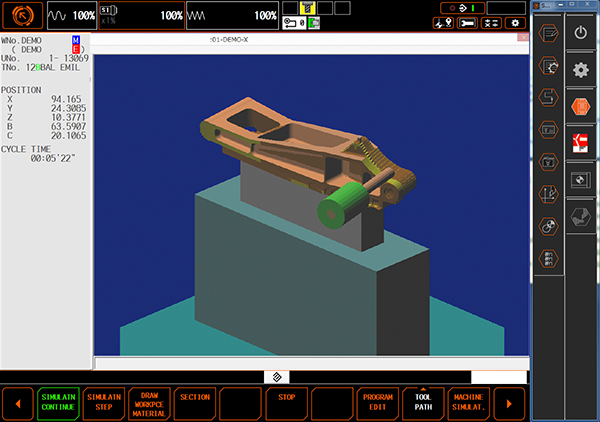

Smooth CAM Ai

Smooth CAM Ai

Efficient workpiece programming in your office

Programs can be made and edited, as well as performing simulation and analysis on the Smooth CAM Ai for multiple machines. These data are sent to machines in the factory for fast and accurate machine setups.

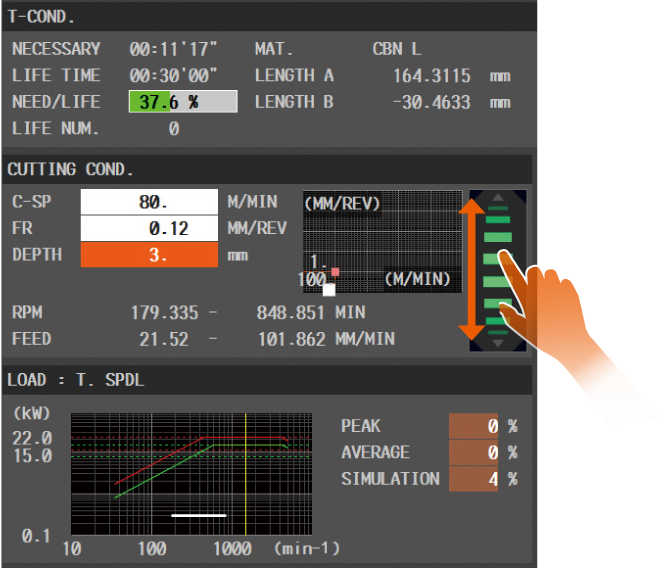

Cutting Adviser

Cutting adviser optimizes machining conditions by MAZATROL SmoothAi CNC and MAZATROL Smooth CAM Ai simulation.

- Tools

- Material removal amount

- Machining load

- Machining time

- Cutting speed

- Feedrate

- Depth of cut

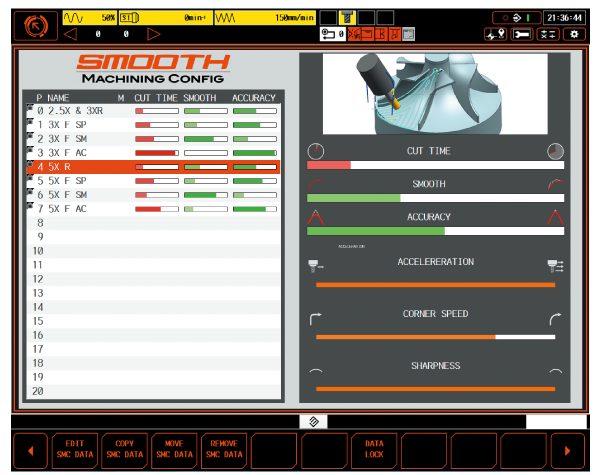

SMC (SMOOTH MACHINING CONFIGURATION)

SMC (SMOOTH MACHINING CONFIGURATION)

Tuning machining features

Machining features including cycle time, finished surface and machining shape can be adjusted by slider switches on the display according to material requirements and machining methods.

This is especially effective for complex workpiece contours defined in small program increments.

Once the desired results are obtained, the settings can be stored in memory so that they can be easily used again in the future. Additionally, the rotary axis acceleration tuning parameter can now be adjusted by a slider switch as well as selecting speed priority or accuracy priority.

These operations can be performed by both the Smooth CAM Ai and MAZATROL SmoothAi CNC.

![]()

![]()

![]()

![]()

Machining features including cycle time, finished surface and machining shape can be adjusted by slider switches on the display according to material requirements and machining methods.

Once the desired results are obtained, the settings can be stored in memory so that they can be easily used again in the future.

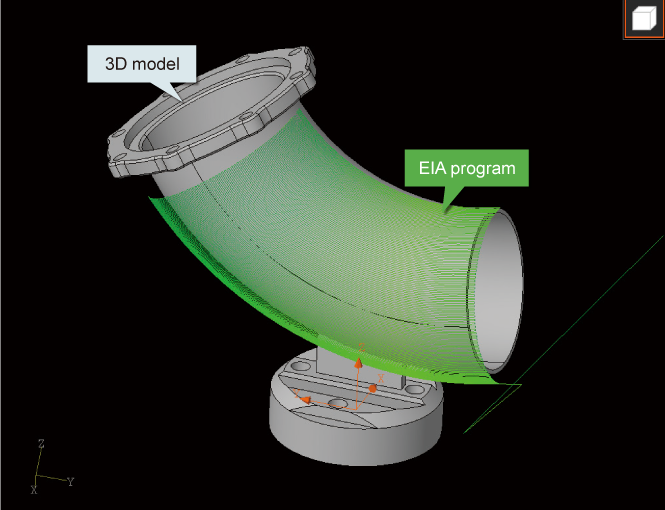

SMC PLUS

SMC PLUS

Optimize EIA programs utilizing 3D models

Compares tool contact point of EIA program with 3D model so that program points can be changed to ensure the correct tool path and high accuracy finished surfaces.

This is optionally available for the MAZATROL SmoothAi.

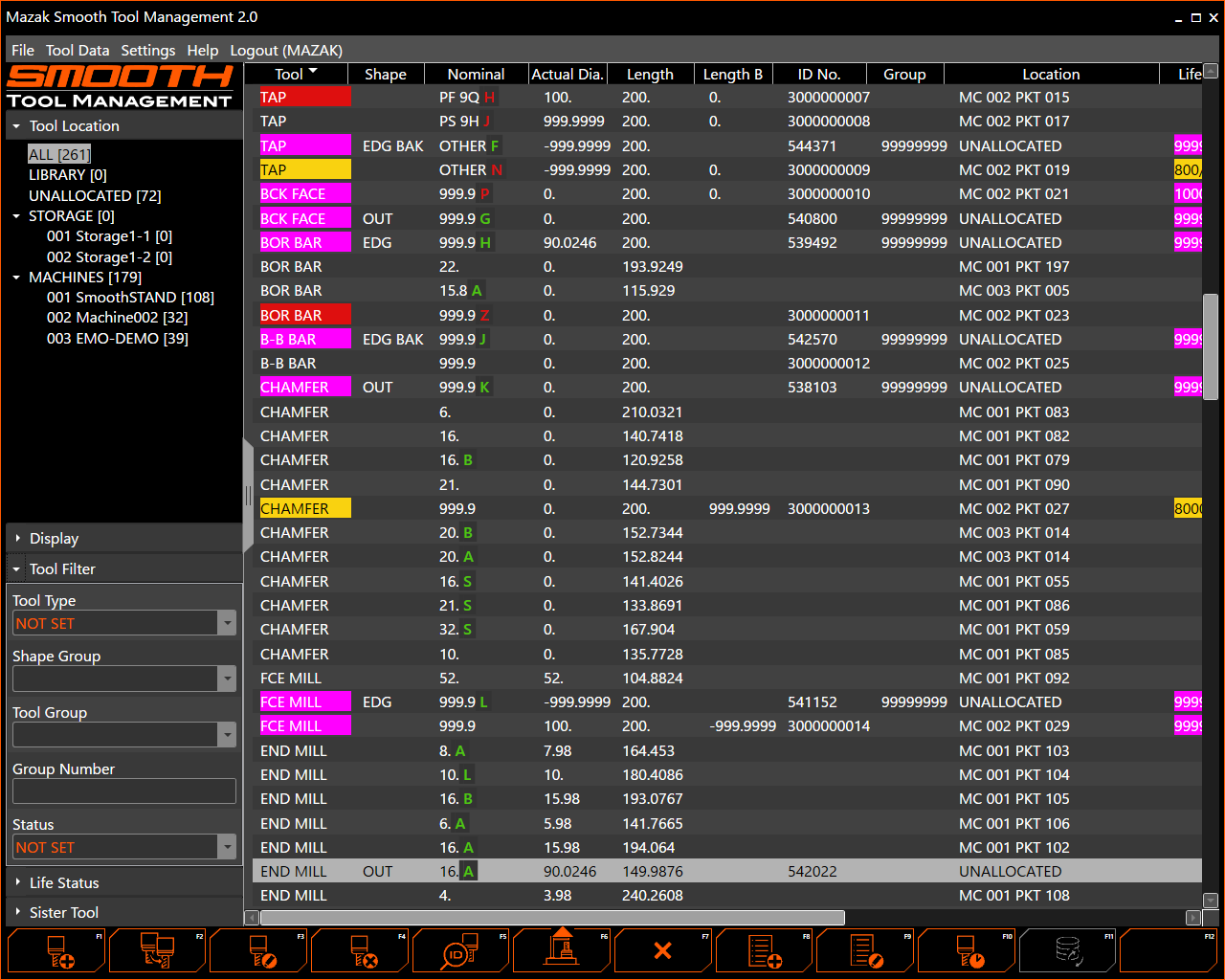

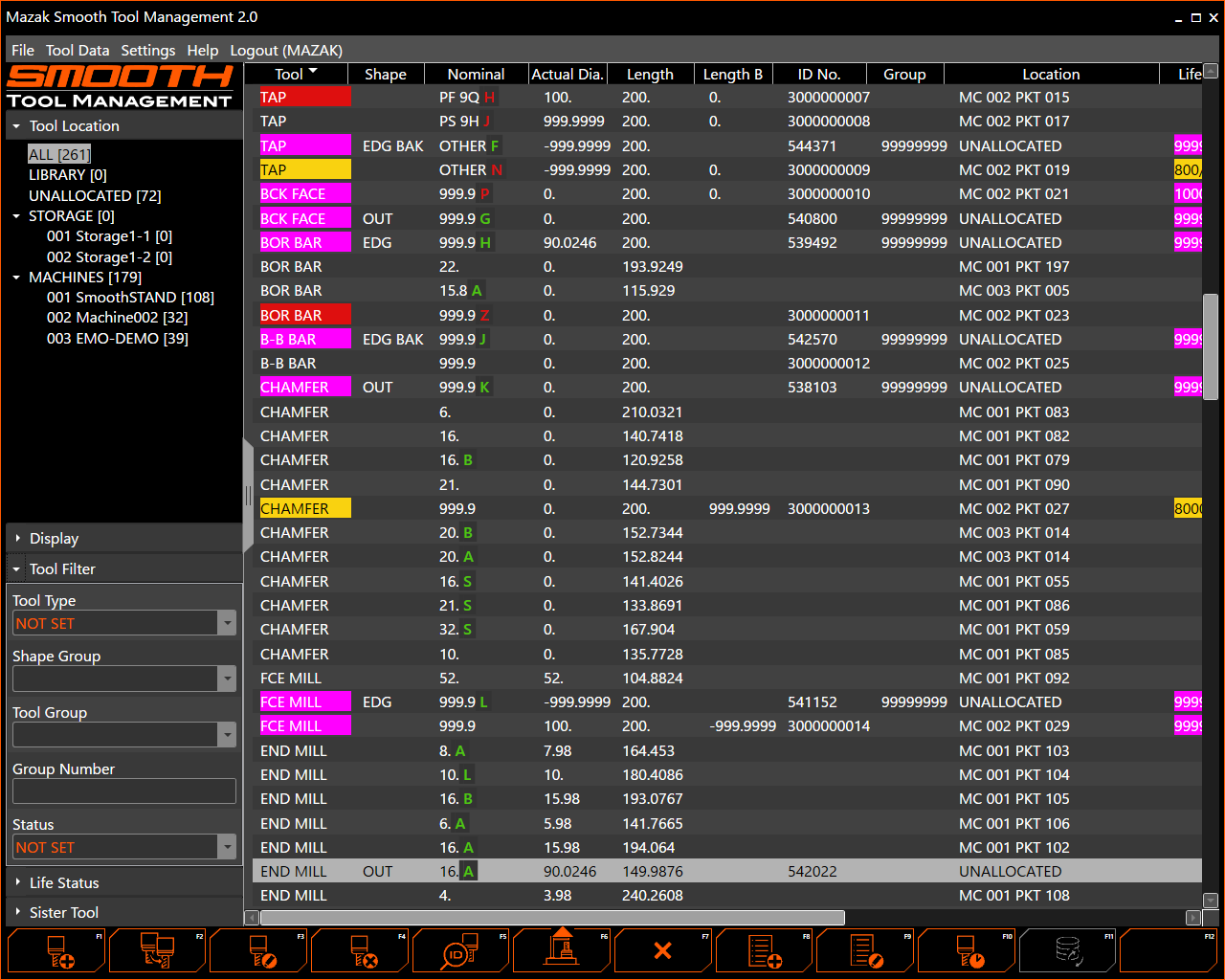

Smooth TOOL MANAGEMENT

Smooth TOOL MANAGEMENT

Manage and visualize tools in the factory for higher production efficiency

The Smooth Tool Management software manages data of the large number of tools in use by a factory.

By centrally managing tools and registering tool data as well as tool setup, machine non-cutting time can be reduced.

This software can also eliminate tool information input errors in the CNC to improve productivity.

Check the status of tools in the magazine of all machines over the network.

Tool diameter and tool length measurement results from Tool Presetter are entered into tool data database.

By reading tool ID, the corresponding data for each tool can be transferred to each CNC system.It can also eliminate tool information input errors in the CNC to improve productivity.

Smooth Process Support Software

The Smooth Process Support software incorporates Mazak’s accumulated expertise to visualize production for convenient factory management.

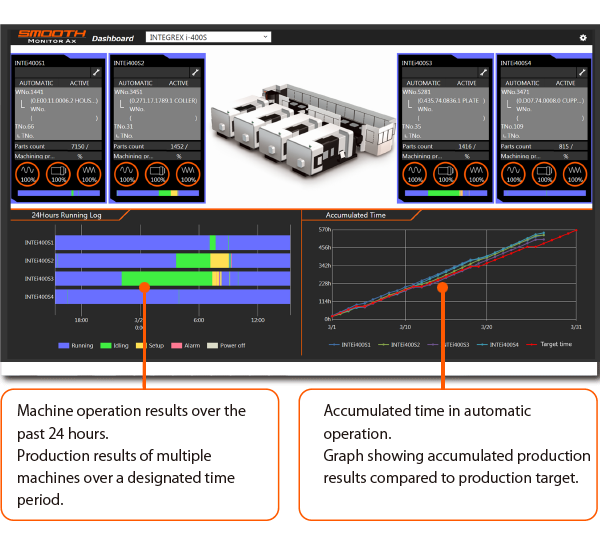

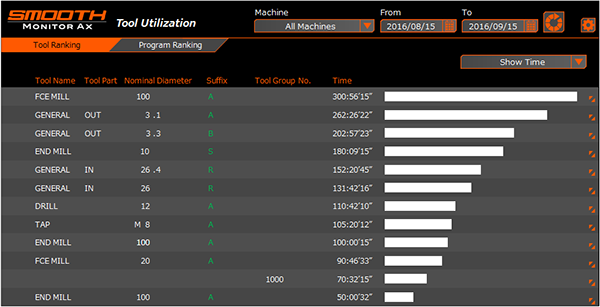

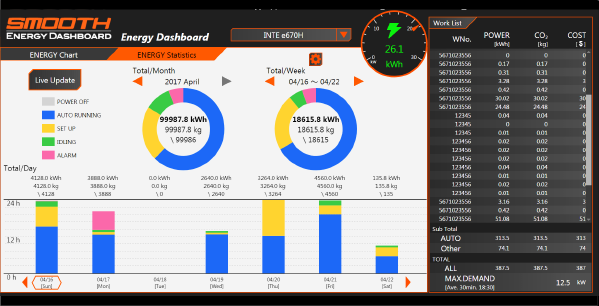

Smooth MONITOR AX

Smooth MONITOR AX

Monitors machine operation status by connecting machines in a factory over a computer network.

By analyzing accumulated operation results, overall factory productivity can be improved.

Operation results of each machine are graphically displayed.

Visualization of factory status.

Status can be displayed on smartphone or tablet.

Visualization of factory status resulting in improved productivity and efficient factory management

Operation analysis display

Tool monitoring display

Maintenance display

Energy consumption display

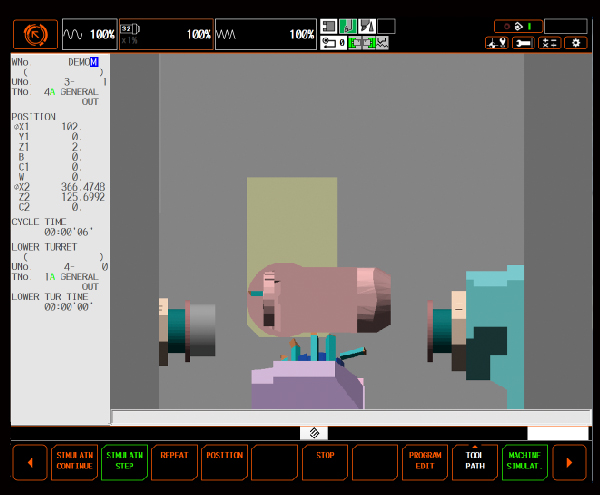

Smooth CAM RS

Smooth CAM RS

Fast programming and simulation of the MAZATROL SmoothX and MAZATROL SmoothG CNC systems in an office using the same operation method as on the shop floor.

Machine interference check for machines equipped with the MAZATROL SmoothX and MAZATROL SmoothG CNC systems can be performed in an office. Accurate interference checks and setup time reductions can be done for machines on the shop floor since the same machine data, tool data, machine parameters are utilized by the Smooth CAM RS.

INTEGREX i-200ST; machine simulation

VARIAXIS i-600; machine simulation

Virtual machining for five-axis machining programs for machines equipped with the MAZATROL SmoothX CNC can be performed which provides fast work simulation and machine simulation.

Five-axis machining; work simulation

MAZATROL programs for the MAZATROL SmoothX and MAZATROL SmoothG CNC systems can be converted for use by earlier versions of the MAZATROL CNC. (There are some conversion limitations.)

Smooth TOOL MANAGEMENT

Smooth TOOL MANAGEMENT

Manage and visualize tools in the factory for higher production efficiency

The Smooth Tool Management software manages data of the large number of tools in use by a factory.

By centrally managing tools and registering tool data as well as tool setup, machine non-cutting time can be reduced.

This software can also eliminate tool information input errors in the CNC to improve productivity.

Check the status of tools in the magazine of all machines over the network.

Tool diameter and tool length measurement results from Tool Presetter are entered into tool data database.

By reading tool ID, the corresponding data for each tool can be transferred to each CNC system.It can also eliminate tool information input errors in the CNC to improve productivity.

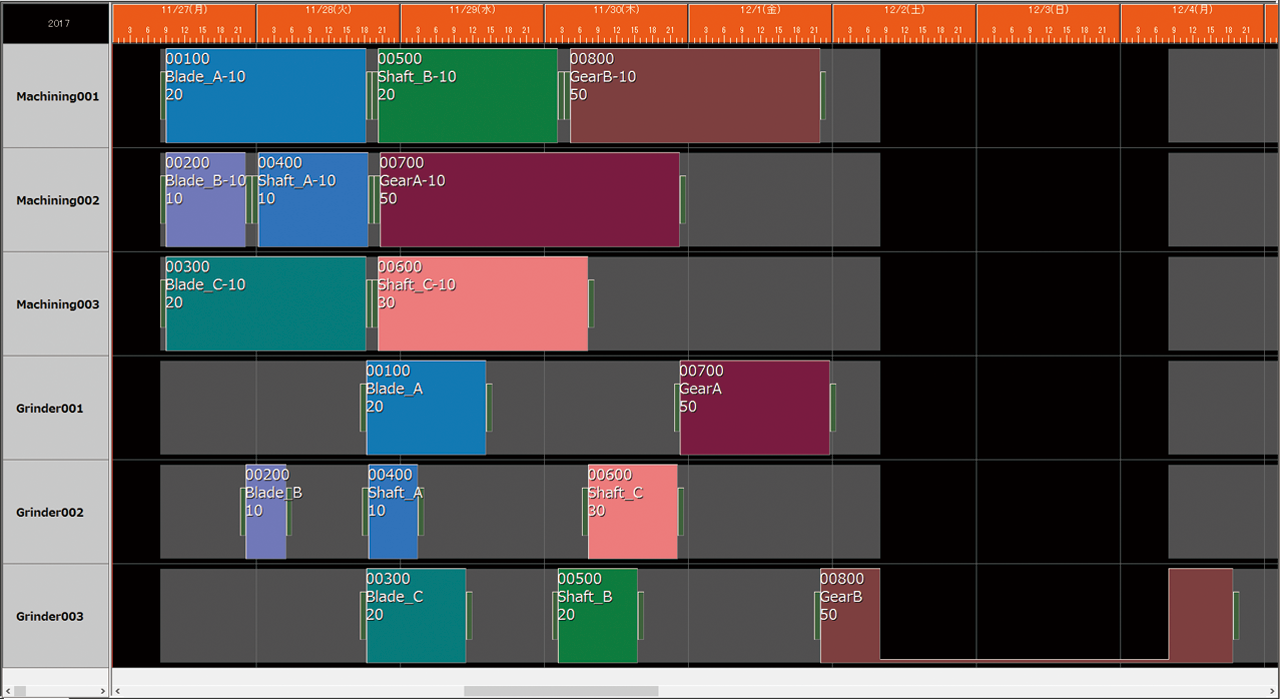

Smooth SCHEDULER

Smooth SCHEDULER

Designed to prepare the optimum production plan by for multiple machines and multiple machining operations

- Visualizing Production Floor

- Reduction of in-process inventory

- Quick and Accurate Response to Delivery Deadline

- Improved Machine Utilization

Visualization of production floor is by displaying the Gantt-Chart schedule.

Production plan up to several months in the future can be easily visualized as well as forecasting completion dates.

Additionally, the work load for each machine and the production processes are visualized.

The instructions for parts to be machined by in the factory are provided over the network.

The Smooth Scheduler status is updated by receiving a completion report each CNC unit and terminal device after machining completion.*

*Progress confirmation is performed from portable terminals, other PCs, etc., by installing the satellite software.

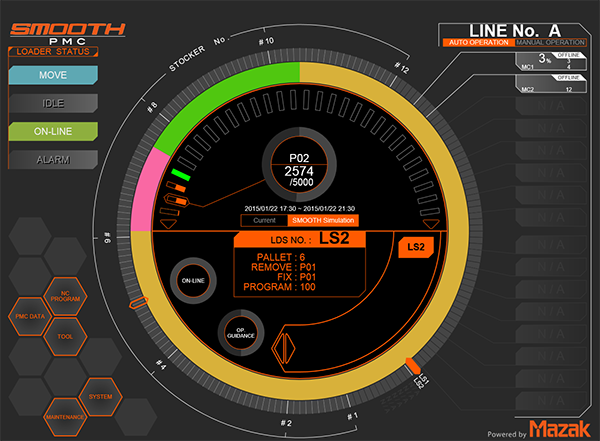

Smooth PMC

Smooth PMC

Smooth PMC is the software to perform schedule automatic operation/control of FMS [PALLETECH SYSTEM] by MAZAK

Thanks to real time simulation, production status up to a week in the future and tool resource check during automatic operation can be done for unmanned operation over extended periods of time.

Smooth PMC generates production schedule.

Schedule and Operation Status can be checked during automatic operation

Automatic operation for up to one week can be simulated. This is used to forecast the required tools, production output and machine loads.

There are 2 scheduling methods (1: By pallet number 2: By part number for precise control) to meet production requirements.

Set production and one piece production flow can also be performed.

Thanks to visual results display,operation status can be conveniently analyzed.

Easy to understand display

If connected to a network (prepared by user), system data are accessible on office PCs, tablets and smart phones.

Intuitive operation thanks to touch panel. Keyboard and mouse can also be used.

HDD data storage utilizes RAID to ensure high reliability. UPS (uninterruptible power supply) is also standard equipment.

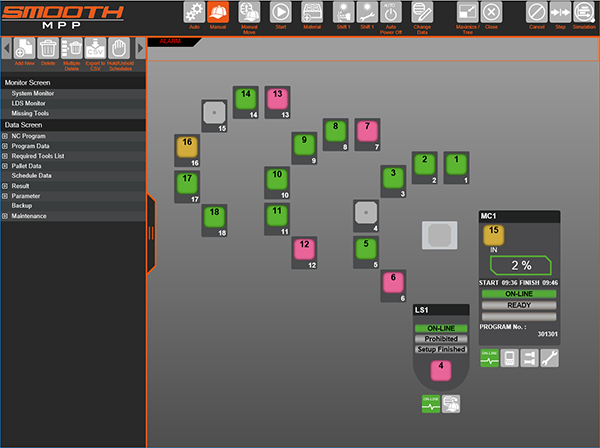

Smooth MPP ( Compact multiple pallet stocker system )

Smooth MPP ( Compact multiple pallet stocker system )

Once the production schedule is input, operation will be performed automatically

Production results, system utilization and other data can be checked on the MAZATROL SmoothX CNC.

The operation and management of the MPP is performed by the same software used by the Mazak FMS system, which is highly regarded worldwide for its ease of operation and high productivity. System and production status are displayed visually. A wide variety of graphs display the production results for convenient system utilization analysis.

System monitoring screen