Fanuc boasts the industry's widest range of palletising robots, providing an extensive variety of options for size, payload capacity, and speed including the world’s fastest palletising robot.

The world's fastest palletising robot

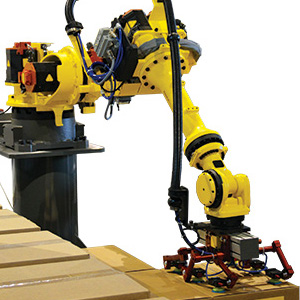

The Fanuc M-410iC/110 palletising robot is designed for high-volume production in case, bag and bottle palletising and de-palletising operations.

This four-axis palletising robot features an exclusive, best-in-class speed for its size and payload, capable of performing 2,040 standard palletising cycles an hour with a 110-kilogram payload.

It also features a compact footprint - with a 646-millimeter interference radius, this palletising robot was tailor-made for tight workspaces.

It’s slim arm and through-arm cable routing simplify dress-out and minimize interference with tooling and other peripheral devices, giving users peace of mind that the robot and its components are protected while the robot performs with maximum efficiency.

The Fanuc M-410iC/110 palletising robot in this video palletises 32 bags per minute, demonstrating the possibilities of a robotically palletised process through the use of Fanuc robots.

The range or Fanuc robots capable of automating palletising applications

Fanuc’s palletising robots range from collaborative robots to heavy payload robots, and consist of 4, 5, and 6 axes to accommodate different range of motion requirements.

Fanuc palletising robots can be integrated with any of the most common robotic grippers types for the lifting and loading of products including bag style, vacuum, and parallel grippers. Robotic palletising applications may also require integration with Fanuc’s iRVision system to provide guidance for part and location detection. Fanuc palletising robots can also be integrated with force sensors, 3D area scanners, and dual check safety. These technologies all enhance the efficiency, accuracy, and safety of robotic palletising processes.

Fanuc’s robots are used to palletise a number of different product types, including cases, boxes, bags, frozen items, cement blocks, bricks, and rolls. Fanuc robots can be programmed to load pallets in single layers, multi-layers, randomised individual order, or mixed product layers.

Fanuc CR collaborative series robots

Fanuc’s CR collaborative robot series features payloads between 15 kg and 35 kg for light robotic palletising. These robots are designed to operate safely alongside humans without requiring safety fencing. Fanuc’s CR collaborative robots can assist workers with the repetitive lifting and loading of pallets.

Fanuc M-710 series robots

The Fanuc’s M-710 series robots are ideal for lower throughput palletising. The Fanuc M-710iC/50 robot is capable of palletising medium workloads and provides versatile mounting options, including floor and ceiling.

Fanuc R-1000 series robots

The Fanuc R-1000 series robots feature the Fanuc R-1000iA/80F for high speed robotic pallet loading. The Fanuc palletising robots from this series consist of a smaller range of motion, but they make the most of their work envelope with fast cycle times.

Fanuc R-2000 series robots

The Fanuc R-2000 series is one of the most successful robot lines from Fanuc. Robots from the Fanuc R-2000 series can been used for loading pallets in tough conditions, such as in freezers, and for robotic palletising heavy boxes in distribution centers.

Fanuc M-410 series robots

Robots from Fanuc’s M-410 series consist of some of the company’s heaviest lifters. The Fanuc M-410iB/700 robot has a payload capacity of up to 700 kg. The M-410 robots are Fanuc’s most popular palletisers with their reach and payload capacity.

John Hart Automation can streamline your palletising process with a robotic palletising system to make you more productive, competitive and cost effective in today’s tough global market

From concept and design, through manufacture and commissioning to training and backup support, we develop sound engineered solutions to deliver a complete turnkey robotic palletising system to overcome your palletising challenges.

John Hart Automation also offers the complete range of Fanuc palletising robots through an Australia wide network of branches including Adelaide, Brisbane, Melbourne, Newcastle, Perth and Sydney.

As Fanuc’s only exclusive distributor of Fanuc robots in Australia, John Hart Automation is the one-stop-shop for the complete range of Fanuc palletising robots.