FLSmidth ABON, located in the suburbs of Melbourne, Australia, is a leading manufacturer of crushing equipment for the worldwide mining industry. Their products are mainly used in mining operations of mineral resources such as a coal, iron ore and copper and also used in various industries such as quarry applications, smelter applications, fertilizers, or cement plants. The ABON brand has sustained and continued growth stemming from recognition and acceptance of its products by major resource and mining companies.

ABON, established in 1964 with incorporation taking place in 1967, joined the FLSmidth Group, which is a leading supplier of equipment and services to the global cement and minerals industries, in 1998. FLSmidth ABON's product life-cycle approach helps customers to reduce emissions, lower operating costs and enhance productivity based on a unique combination of key products, process expertise and service solutions.

A crusher is a machine designed to break large rocks into smaller rocks. Crushers may be used to reduce the size, or change the form, so that they can be more easily and effectively handled. The development of diversified products is demanded by customers based on the materials or the use of the object that is crushed.

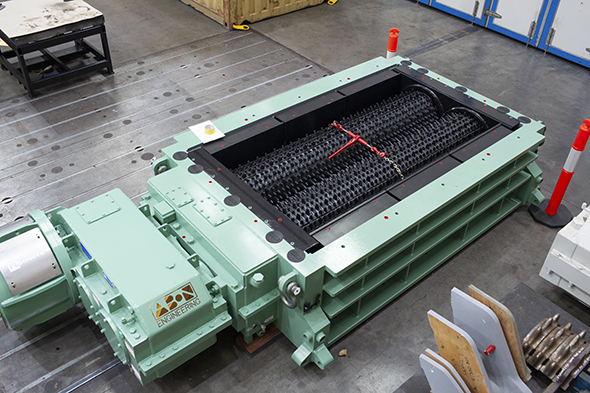

Assembled FLSmidth ABON Sizer crusher

The main products of the company are Twin Roll Sizers crushing the materials, Roller Screens sieving the materials according to size and Chain Feeders feeding the materials into machines and transporting them. The ABON products have been commissioned in Primary, Secondary, Tertiary and Quaternary process from rough crush to fine crush. Thanks to the simple machine structure and durability, machine design leads to suppress the cost and the load for maintenance.

Neil Paxman CNC Machinist (left) and David Colasante CNC Manager (right) with Sizer Assembly

Additionally, the products generate a minimum of fine particles and low noise levels. FLSmidth ABON is a world-leading technology company whose countless innovations in engineering have pioneered the minerals handling and minerals processing industries for more than 50 years.

Shortening processing time by integrating machining process

ABON previously manufactured their shaft components on multiple machines in several setups, resulting in long in-process time. After extensive study of the best available machinery and submissions from John Hart, Abon's first Mazak acquisition was the Mazak INTEGREX e-650H 6000U in 2005. "We can finish various sizes of shafts in just two setups with better quality and minimum in-process times," reflected Mr. Phillip Mulcahy, General Manager. "The ability to consolidate multiple operations with minimal setup time and reduced cycle time are key benefits of our investment in Mazak."

David Colasante CNC Manager (left) and Phillip Mulcahy General Manager (right)

Product innovation defines their approach

Following the success of this first installation, ABON has introduced five Mazak machines including the INTEGREX e series in 2017. All are used to machine gears by the Smooth Gear Skiving and Smooth Gear Milling functions. An INTEGREX e-800H is used for spline processing on long shaft components by using the Smooth Gear Hobbing function. Especially for long shaft processing, in-process time was substantially reduced - from three weeks outsourcing to several hours. Mr. David Colasante, the CNC Manager emphasizes the investment effect saying "We continue to refine our production processes to be responsive to the ever challenging demands of our customers."

Mazak Integrex e 800H 8000U

Growth for the resource industries is further expected due to the increasing demand in energy consumption with the economic development in Asia. ABON's manufacturing facility is constantly updated with the latest technology manufacturing equipment for product innovation. FLSmidth ABON is ideally positioned to offer customers the best solutions and will continue to contribute to mining mineral resources in the future.

Mazak Integrex Alley at FLSmidth ABON