Innovative rollfeed turning process

A partnership for unequaled performance: Together with Vandurit, OPEN MIND developed a CAM strategy that is perfectly aligned with the innovative rollfeed turning process. The use of these inserts with particularly large radii results in significant time savings.

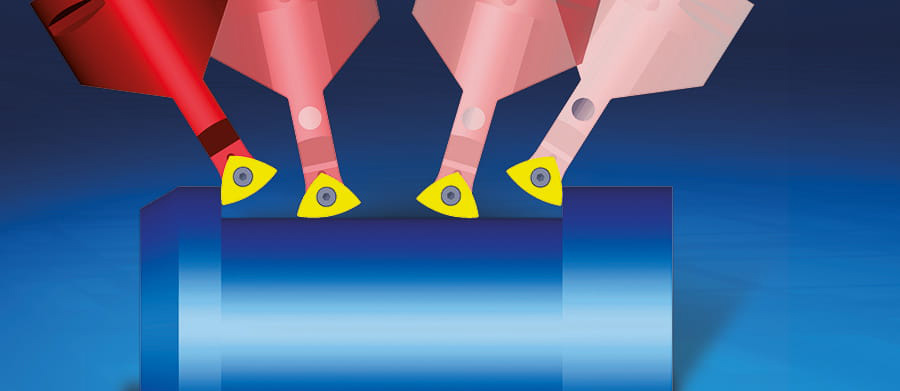

Thanks to the new rollfeed turning-rolling inserts from Vandurit and the perfectly adapted hyperMILL rollfeed turning strategy, flawless workpiece contours can be achieved in no time at all. What makes this turning method so clever is how the tool’s cutting edge rolls off the workpiece surface – which can have any contour. The large radii on the insert, ranging from 17 to 19 mm, allow a much higher feed rate and greater cutting speed than with conventional inserts and deliver a twist-free finished surface.

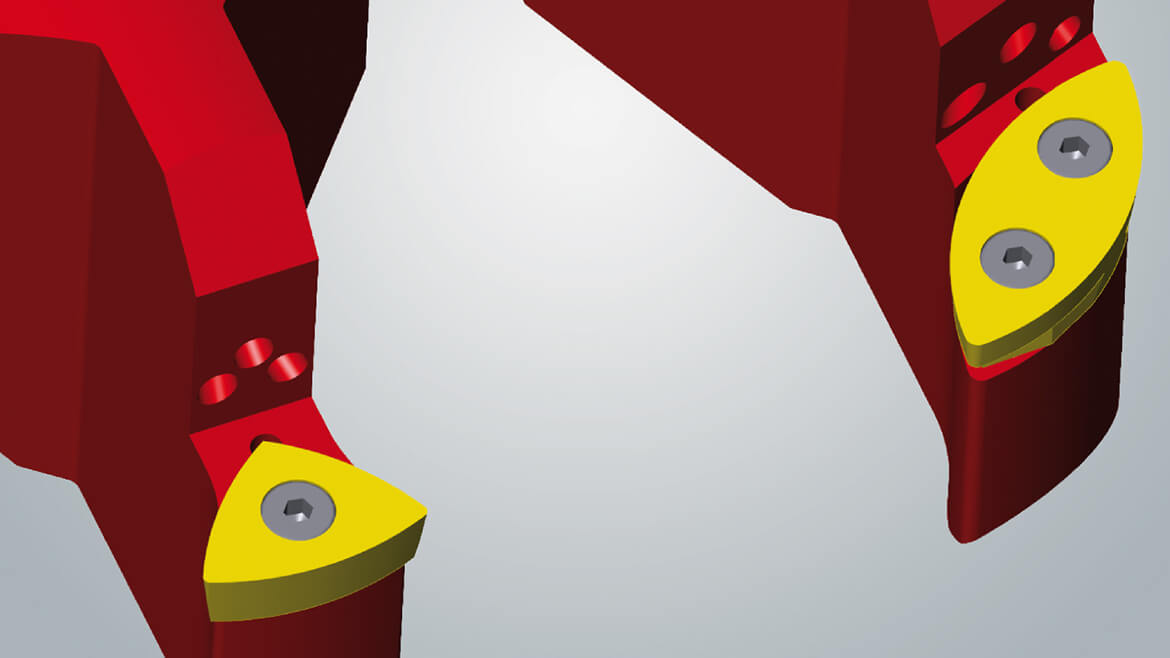

rollfeed indexable inserts

Sometimes less is more. Only two rollfeed indexable insert geometries are required for finishing. The T insert is suitable for machining up to three workpiece sides; the X insert allows for processing up to two workpiece sides.

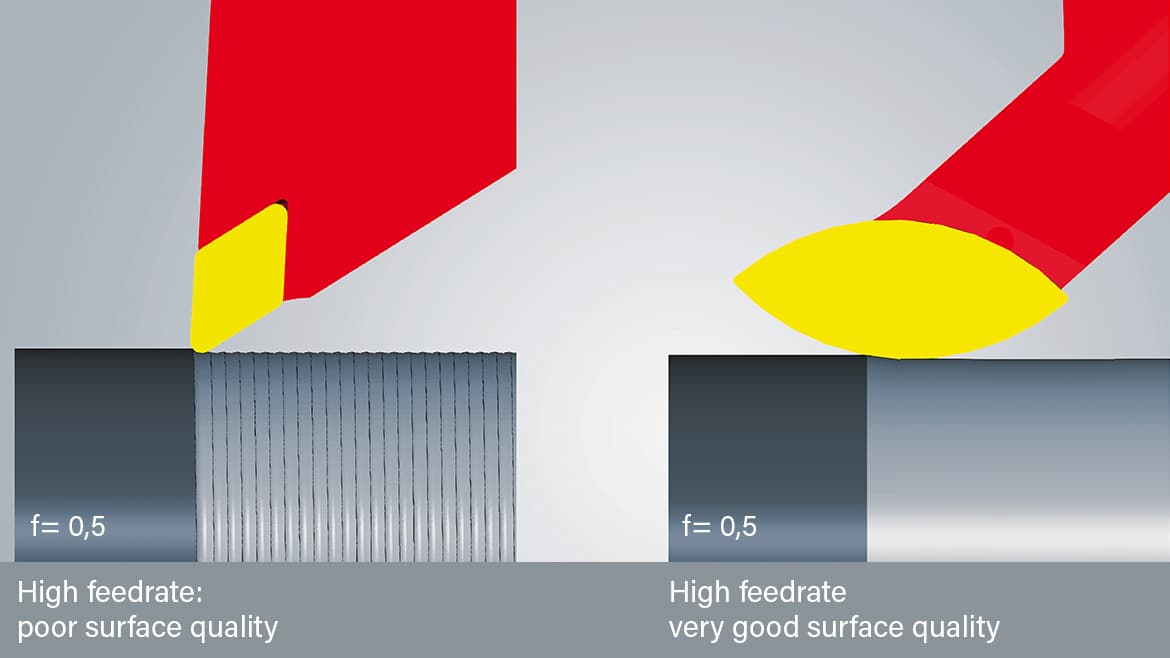

Perfect surfaces despite high feed rate

The rollfeed indexable inserts achieve a significantly better surface quality than conventional inserts with a radius of only 0.4 mm or 0.8 mm, especially at high feed rate. The improved cutting conditions also extend the service life of the rollfeed tools by 300-500 percent.

Features

- Highly efficient process

- Generates perfect surfaces free of twists

- Simple to program

- Fewer tool changes

- Undercuts can be integrated into rolling movement

- Tool life extended by 300-500%

Areas of application

- All materials can be machined

- Use of any cutting material for turning inserts possible

- Suitable for inside and outside machining

- Diverse applications: for plane levels, cylinder, convex, and concave surfaces, as well as for inclinations and grooves