Roboguide is a robot system animation tool specifically developed for the production and maintenance of robot systems. It can be used both in offices and on the factory floor.

As the Australian market continues to suffer from skilled labour shortages and the focus on OH&S grows, customers are coming to John Hart to discuss new and more productive Fanuc robot solutions.

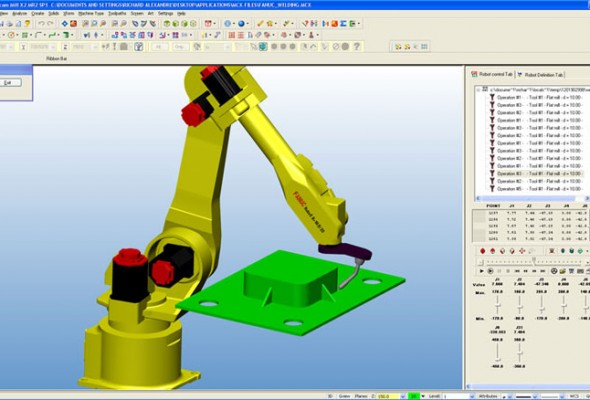

A valuable tool that greatly assists the development and demonstration of these solutions is the Fanuc 3D robot simulation package Roboguide. Roboguide is a cost effective software package that enables our engineers to design, prove and program robot systems in real time, either concurrently in a new product design or for making modifications to existing equipment or programs.

Roboguide provides John Hart engineers with the tools needed to develop and test a complete robotic application in a 3D environment without the time and costs associated with developing a prototype work cell.

For customers who are considering automation, Roboguide can quickly and easily provide reliable and accurate information about a given application. This helps in reducing the amount of time taken to design and test a solution, and speeds up the assessment of a project’s viability.

Roboguide can import unique CAD models of process parts and create a virtual work cell which includes machinery, part transfer devices and factory obstacles. Roboguide will then teach robot paths to simulate the operation and performance of the robotic application taking into account the physical obstacles.

Also simulated in Roboguide’s 3D environment is reach verification, collision detection, accurate cycle time estimates and other visual system operations. These functions can be used to produce a simulation video to help evaluate and approve a project.

Whether it is to assist design, simulate, install or commission a robotic system, JHA&R apply these technologies to a wide range of applications in areas such as material handling, machine tending, picking, packing, palletising and material removal.

- Animation tool easily enables a quick and low cost verification of robot application systems

- Easy to create the environment for devices and machines. Special skills are not required.

- Program creation using animation

- Extreme reduction of start-up time and maintenance time by off-line check in a shop floor

- Standard Package which supports various robot application

- Robot application specific package with high operability.

Features

Cell Calibration And User Frame

Roboguide automatically creates reference programs in order to calibrate the simulation to the real robot system. Three taught robot positions allow adjusting the entire process.

Collision Detection

Collision detection feature to get a visual warning in case of collisions during the robot simulation

Easy Programming Of Standard

Application software packages can be selected and configured with ROBOGUIDE. This reduces system cost and drastic accelerates system start up.

Easy To Use Powerful Offline Programming Software

- Roboguide allows powerful programming with an intuitive and easy-to-use interface

- Cell Layout and Cycle Time can be tested Offline

- Virtual controller technology for true cycle times and reach

- All robot models can be simulated. ArcTool, SpotTool and HandlingTool application software can be selected and configured.

- Easy to use with Virtual Teach Pendant (Same menus & displays as the real robot)

- Offline Programming speeds system integration and reduces system cost

- Cycle time profiler, collision detection & work envelop display

- Motion trace displayed as node map; AVI video file output

- Import of work pieces, tools, fixtures and obstacles in IGES format

Graphical And Video Display Of Robot Programs

- Motion trace displayed during testing

- AVI video file output possible

- Graphical output of results for quick documentation and decision making

Import Of CAD Data In IGES Format

Imported formats help build system layouts and evaluate system operation quickly and comprehensively.

Profiler Function

The teach pendant program profiler analyses the timing of each program line in order to achieve best cycle times.

Virtual Teach Pendant

Easy to use with same menus & displays as the real robot

No special training necessary

PC Developer

Developer’s Kit is a powerful tool that enables high performance communication of information and instructions between a PC and FANUC System R-30iA and R-30iA Mate Controllers. The kit is both a development and run-time environment that gets the MS Windows™ application running quickly. Visual Basic programming expertise is required to develop application packages over PC Developers Kit.

Features

- Robot Server

- Robot Manager

- FTP (File Transfer Protocol) for file access

- Visual Basic Integrated

- Development Environment

- Visual Basic Programming

- Online documentation

- Source files for example programs that use all Robot Server features

Robot Server

The heart of the PC Developer’s Kit is the Robot Server. It knows how to access the information needed from the R-30iA and R-30iA Mate Controllers and makes the controller follow the instructions.

The Robot Server works with Visual Basic 6.0 code through an object oriented interface. When using an object’s property, method or event, the object handles the details of getting that action accomplished on the robot

in the most efficient way. Programming with objects is fundamental to Visual Basic. Visual Basic’s rapid prototyping and powerful development environment and Robot Server objects virtually ensure the success of the application.

Here is a partial list of the actions the application can do through the Robot Server:

- Read/write variables – this includes user defined structures, arrays and path nodes along with the “simple” system and KAREL variables.

- Robot Manager

- Read/write numeric registers – these are the variables of TPP programs.

- Test or set I/O – all types (e.g. DI, DO, AI, AO, GI, GO, SI, SO, UI, UO, etc.) of I/O supported by the controller can be accessed.

- Configure I/O – allows user to configure controller I/O.

- Check program status – determine which program is running, aborted or paused.

- Load/save programs – users can load a program to controller memory and save it to the PC.

- Read/write positions – positions can be converted and presented in joint, cartesian or matrix representations. This includes KAREL positions, TPP positions, position registers, the current robot position, user frame, tool frame, jog frame and positions in system variables.

- Monitor alarms – the entire alarm log is made available and updated as new alarms occur.

- Coordinate with the robot program – TPP and KAREL programs can generate events to which the Visual Basic code responds.

- Monitor variables, I/O, program status – display and update robot information on the PC screen through event handler.

Robot Manager

The Robot Manager controls and monitors connections between the Robot Server and the R-J3 and R-J3iB Controllers. It offers the following features:

- Connection sharing between multiple applications

- A directory of available robots and their current status

- Disconnect detection and automatic reconnect

- Robot Server keep-alive

FTP

PC Developer’s Kit relies on the industry standard FTP protocol to enable the application to list, read, write and delete

Visual Basic’s Integrated Development Environment

PC Developer’s Kit takes full advantage of Visual Basic’s Integrated Development Environment (VB-IDE). Here’s how it fits into the extensive features of the VB-IDE:

- Context sensitive help – press F1 while the cursor is on any of the Robot Server object components and read more about it.

- Statement builder – Visual Basic knows about the robot server’s object interface to anticipate the next keystroke and give the argument list for available robot object property or method.

- Object browser – all the robot server’s object interfaces are shown; Use F1 for context sensitive help.

Visual Basic Programming

Visual Basic programming is needed to access robot information.

See the following example application to get an idea of what it takes to access robot information at the PC. The above example program presents an updated display of the most recent alarm on any robot on the network. Just enter the robot’s network name in the box below and press connect. It has full error handling and many of the lines were automatically generated.