iRVision is Fanuc's unique plug & play visual detection system.

Fully integrated into the Fanuc R-30iB controller, it has been designed to be quick to install, easy to use and ultra-flexible.

Using either 2D or 3D part recognition, it is capable of locating workpieces whatever their size, shape or position. It can also read bar codes, sort according to colour and support flexible parts feeding, high-speed visual line tracking (iRPickTool) and bin/panel picking. The key to increased productivity, iRVision eliminates the need for jigs thereby creating additional cost savings.

Fanuc iR PickTool

Save on software development by using Fanuc's cost-effective queue management tracking software for single robot and multi robot visual line tracking applications. Designed to be easy to use for beginners and experts alike, this tool enables you to create standard as well as custom configurations. Easy to set up via plug & play, it does not require TP programming and can be operated conveniently using iPendant touch.

Fanuc 3D Area Sensor

Completely integrated into the robot controller, Fanuc's high-speed 3D Area Sensor uses vision technology to create instant 3D maps. These enable the robot to indentify and pick loose parts out of a bin and achieve cycle times of 8 to 12 seconds - even if parts are dirty, rusty, oily or, as in the case of bags, exhibit no clearly recognisable features. Set up is easy on PC or the Fanuc iPendant Touch.

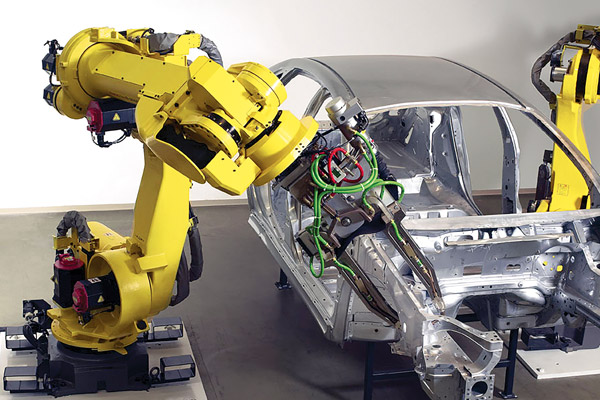

Fanuc iRVision Weld Tip

iRVision Weld Tip Inspection visually inspects and checks the condition of spot welding tips to identify faults. Capable of conducting a variety of tests, this dedicated software enables you to measure cap wear and identify whether a cap has been replaced or dressed.

Fanuc iRVision TorchMate

Designed for the shop floor and fitted with an industrial camera, iRVision TorchMate prevents alignment issues from occurring by keeping the tool centre point exactly on the tool path. Ensuring consistent weld quality, iRVision also increases uptime by eliminating the need for preventive action.